AUTOMATION SYSTEM:

Assembly

Automated machines have revolutionized the assembly process over the past 50 years. Transforming factory floors, assembly automation systems have helped companies improve productivity, quality, and efficiency while reducing cycle time and labor costs. Industries such as medical, pharmaceutical, packaging, automotive, aerospace, and military/defense manufacturers are all increasingly automating their production lines to reduce labor costs and improve efficiency. For over 25 years, Intec Automation has provided custom automated solutions for companies all over the world. Using proactive approaches, Intec Automation delivers world-class machine design, controls engineering, project management, and customer support. Intec customers will immediately see returns on investment. With reliable, robust equipment, Intec ensures that we’ll meet your production needs both now and in the future.

BENEFITS OF CUSTOM ASSEMBLY MACHINES

To achieve optimal supply chain performance, companies must produce high-quality products in the shortest time possible. Using automated assembly systems helps you save time and money. By having custom machinery built and designed for your specific needs, your company will see the following benefits:

- Increased productivity

- Reduced costs

- Improved quality

- Shorter cycle times

- Increased employee safety

- Decreased product loss

- Improved process control

Custom assembly automation equipment improves a variety of manufacturing processes. See below for a few examples of how custom automated manufacturing machines can improve a company’s production needs.

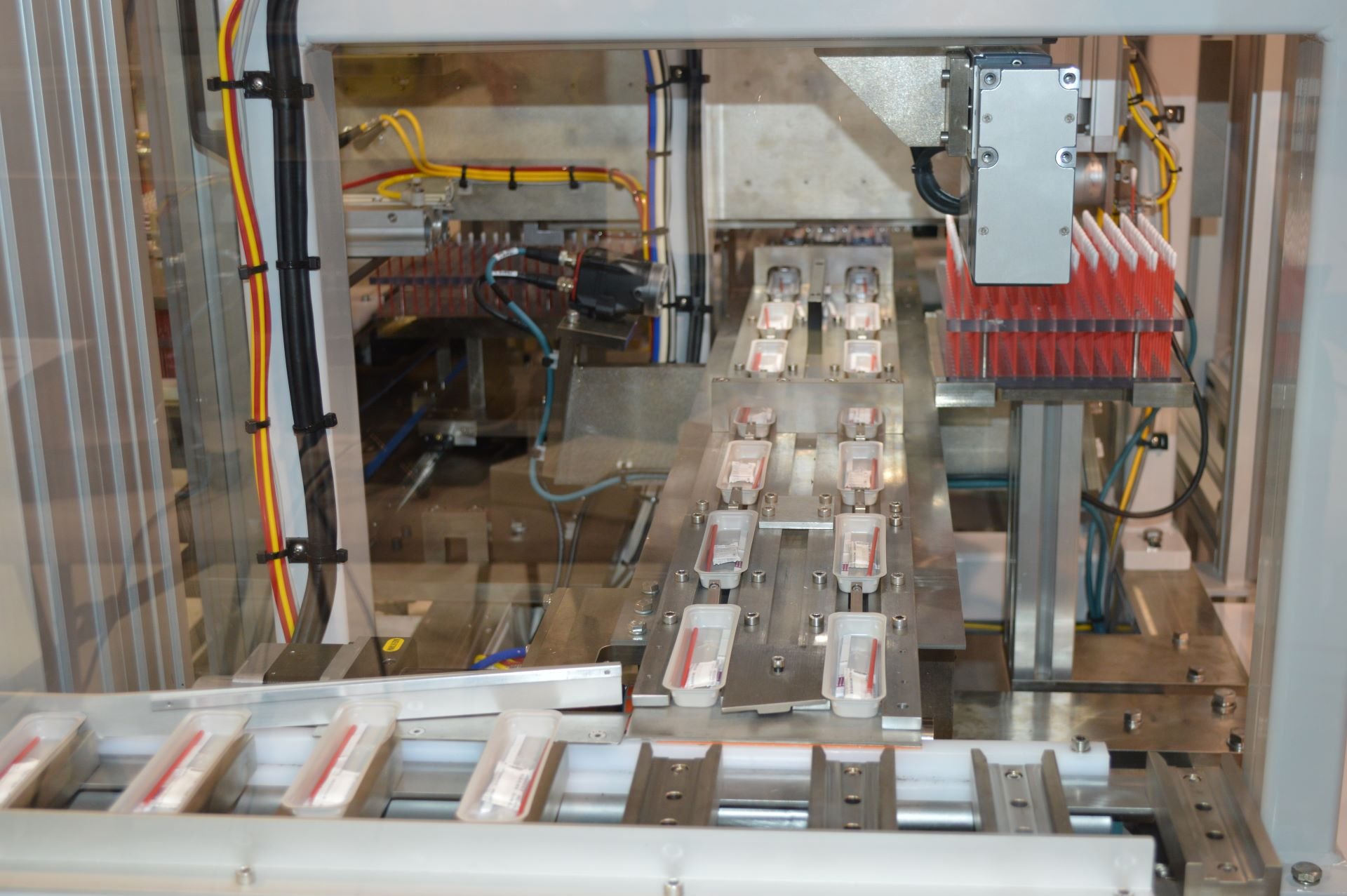

- Your medical diagnostics manufacturing plant needs equipment that can automatically assemble and package a diagnostic test. Intec Automation’s medical kit assembly and packaging machine allows you to assemble the entire multi-component kit, as well as package the kit for sale to the end-user.

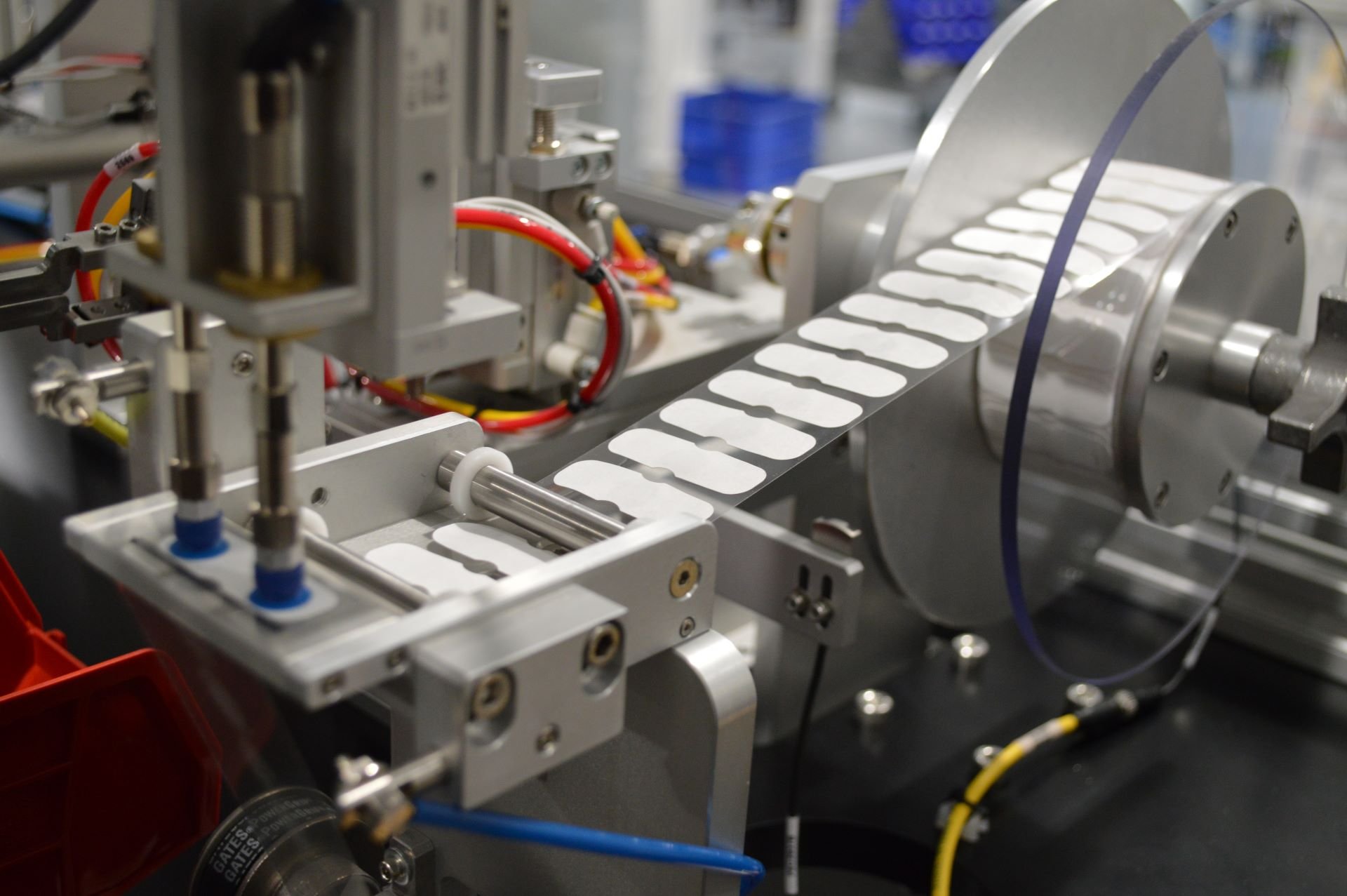

- Various industries require tape application for many products during assembly. Whether it’s for physical attachment or for masking, Intec has been designing and building tape application machines for over 25 years.

Intec Automation offers customized solutions for an array of products. In addition to the machines discussed above, our expertise includes Needle Crimping and Bending, PCR Tubes, and Inline Assembly Machines.

CAPABILITIES

Automated Assembly & Finishing Systems

- Electronic Component Assembly

- Medical Device Assembly

- Adhesive Dispensing Systems

- Tape Application Systems

- Packaging Device Assembly

- Sealing System Assembly

- Connector Assembly

- Powder Filling Systems

- Instrumentation Assembly

- Custom Machining Systems

Process Integration Expertise

- Bulk Feeding / Outfeeding

- Vibratory Bowls

- Centrifugal Systems

- Conveyors

- Elevators

- Vision Guided

- Web Handling

- Trays & Magazines

- Pick & Place

- Orientation

- Inspection / Verification

- Escapement

- End-of-Arm Tooling (EOAT)

- Capping

- Printing

- Labeling

- Lasers

- Inkjet

- Dispensing

- Fluid

- Powder

- Ball Bearings

- Adhesion Promoter

- RFID Reading & Writing

- Data Collection & Storage

- Taping

- Gluing

- Cutting

- Drilling

- Bending / Crimping

- Pressing / Forming

- Stamping / Laminating

- Packaging

- Welding

- RF

- Ultrasonic

- Inspection / QC (Quality Control)

- Sensors

- Cameras

- UV Sensing

- Laser Profiling

- Pass/Fail Segregation

Industries We Serve

For over 25 years, we have been successfully designing and building clean sheet, custom solutions for manufacturers all over the world and in many different industries including but not limited to Medical, Pharmaceutical, & Life Sciences, Automotive, Aerospace, Defense, Hi-Tech, and Consumer Products. Some of our areas of expertise include the following: