project portfolio:

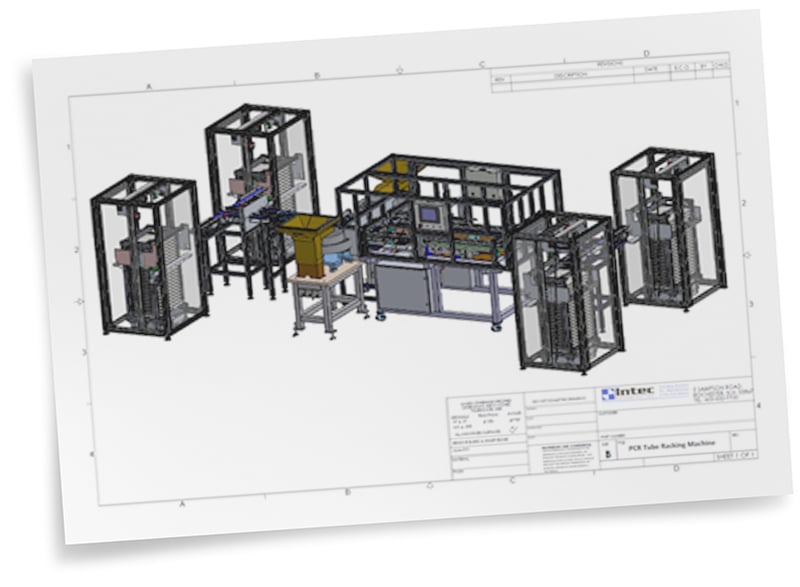

PCR Tube Racking Machine with Bulk Loading / Unloading

HAVE A QUESTION ABOUT YOUR PROJECT?

We are deeply rooted in the medical industry with many large customers and dozens of successful projects.

The Point-of-Care diagnostics industry is ever-growing and enables doctor’s offices and hospitals to quickly diagnose and subsequently treat infectious diseases on the spot, eliminating time consuming and expensive lab testing, and expediting treatment. Often times, these products and devices are in the form of test kits.

About the PCR Tube Racking Machine with Bulk Loading / Unloading

These test kits are comprised of small plastic tubes filled with a special solution to enable PCR testing. Polymerase chain reaction (PCR) is an efficient and cost-effective way to copy or “amplify” small segments of DNA or RNA. Using PCR, millions of copies of a section of DNA are made in just a few hours, yielding enough DNA required for analysis. Previously, amplification of DNA involved cloning the segments of interest into vectors for expression in bacteria, and took weeks. But now, with PCR done in test tubes, it takes only a few hours. Hundreds of millions of PCR tubes are required to supply this market.

Intec supplies machines to this industry that feed, singulate, inspect, rack, and fill PCR tubes. These self-contained systems perform a variety of feeding, loading, inspecting, and offloading operations, including vibratory feed systems, singulating and staging, inspecting, and loading test tubes into 96-well carrier plates. These machines also include a number of inspection points at critical intervals in the process. Various elevator and robotic pick-and-place elements feed and load the components, while our proprietary Linear Transfer Plate motion platform delivers smooth, high speed product movement throughout the process. Donor stations are in place to replace any bad or missing components. Finished PCR racked plates are singulated to an unload module and are automatically offloaded onto carts for internal transport within the factory to downstream operations.

SUCCESS!

In addition to engineering the design and control systems, we built and wired the electrical cabinets and fabricated the machine components in-house. Having direct oversight of the project enabled us to complete it in just 26 weeks. Successful factory acceptance testing, installation, and training took place.

-

Machine Description and Highlights

-

- Uses Intec’s famous “Linear Transfer” motion platform

- Uses a variety of feeding elements like elevators and robotic pick and place

- Performs a variety of feeding and loading operations using load/unload modules, vibratory feeding systems, singulation and escapement, and robotic pick and place using complex sophisticated gripper elements

- Software and HMI is recipe driven with self-diagnostics and production counting

-

Capabilities Applied

-

- Clean Sheet Design and Build

- Mechanical Engineering and Machine Design

- Electrical and controls engineering, panel building, PC and PLC programming

- Program management and technical buying

- In-house fabrication, assembly, test and debug

- Factory acceptance testing, training and installation assistance

-

Delivery/Turnaround Time

-

26 weeks

We are ready to make a personal investment in your success

Our automation strategies are unique, game-changing, and deliver the flexibility to adapt to shifting production requirements. We offer value-driven solutions that add intelligence and economy to your operation. Let's talk about what's on your plate and about how we can work together to make your life a little easier.