AUTOMATION SYSTEM:

Vision Inspection

Intec Automation has over 25 years of experience performing machine vision integration for diverse industry clients. We manage a 30,000 square foot facility with top-of-the-line equipment, allowing us to take your project from concept to reality with no outsourcing. We also take a unique client-focused approach that involves your feedback at every step. By working with you one-on-one to understand your constraints and capabilities, we achieve decreased cycle times, quality improvement, and increased worker safety, all while reducing overall operating costs.

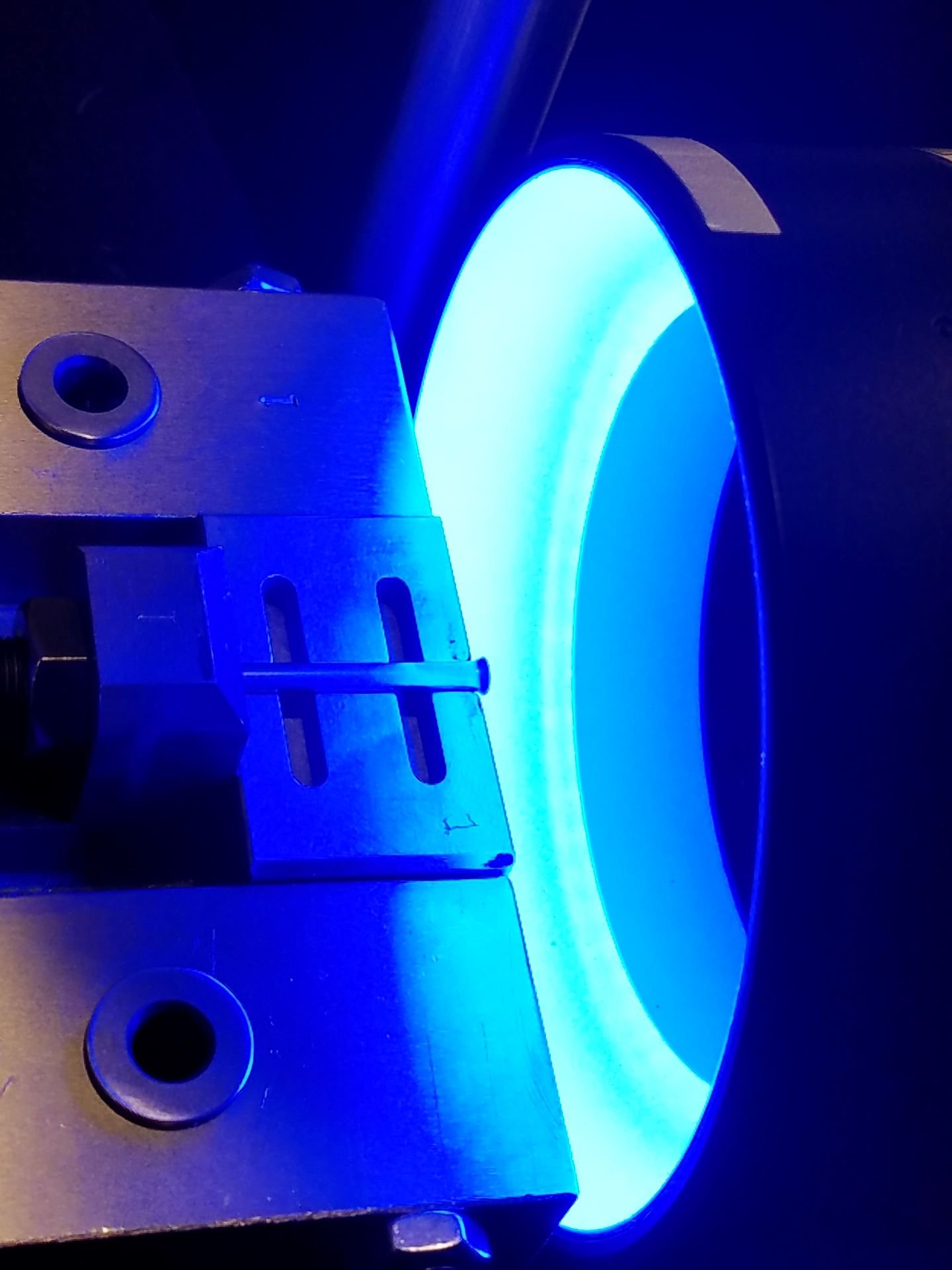

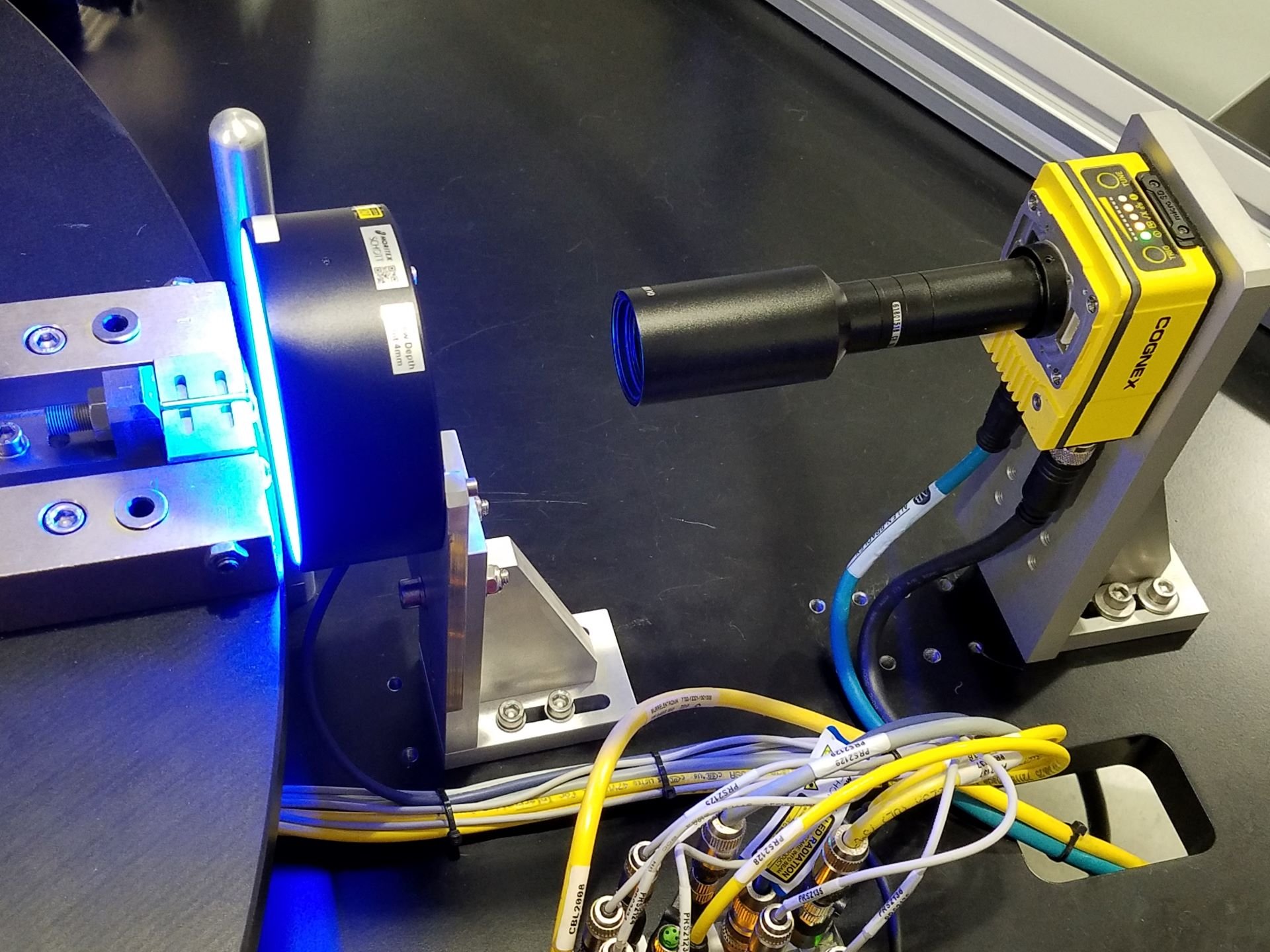

Automation vision inspection systems represent an advanced set of technologies designed to streamline quality control, inspection, and data collection. The devices capture photographs throughout an automated manufacturing process, which can then be used to extrapolate important information about performance. Facility managers are increasingly turning to these technologies as an accurate, expedited method of quality control automation.

WHAT IS A VISION INSPECTION SYSTEM?

You might compare a vision inspection system to the “eyes” of an automated manufacturing process: they visualize the ongoing production as an important check on what’s being put out. Extending from this basic functionality, vision inspection systems can possess a broad range of capabilities depending on their intended use. They can be programmed to:

- Detect the presence or absence of a given element within the system

- Verify product elements like barcodes or colors, or identify defects

- Guide robotic processes like sorting, assembly, pick-and-place, or dispensing

- Inform calibration processes

- Determine pieces and parts orientation and position so that robots and other pick and place elements can be used effectively

These systems bring an additional layer of accuracy to critical processes in industries that require precision at every stage.

WHY USE AUTOMATED VISION INSPECTION SYSTEMS?

Applications

Vision inspection systems are used across a broad range of manufacturing techniques, often serving roles that are difficult or impossible for humans. Some of their core applications include:

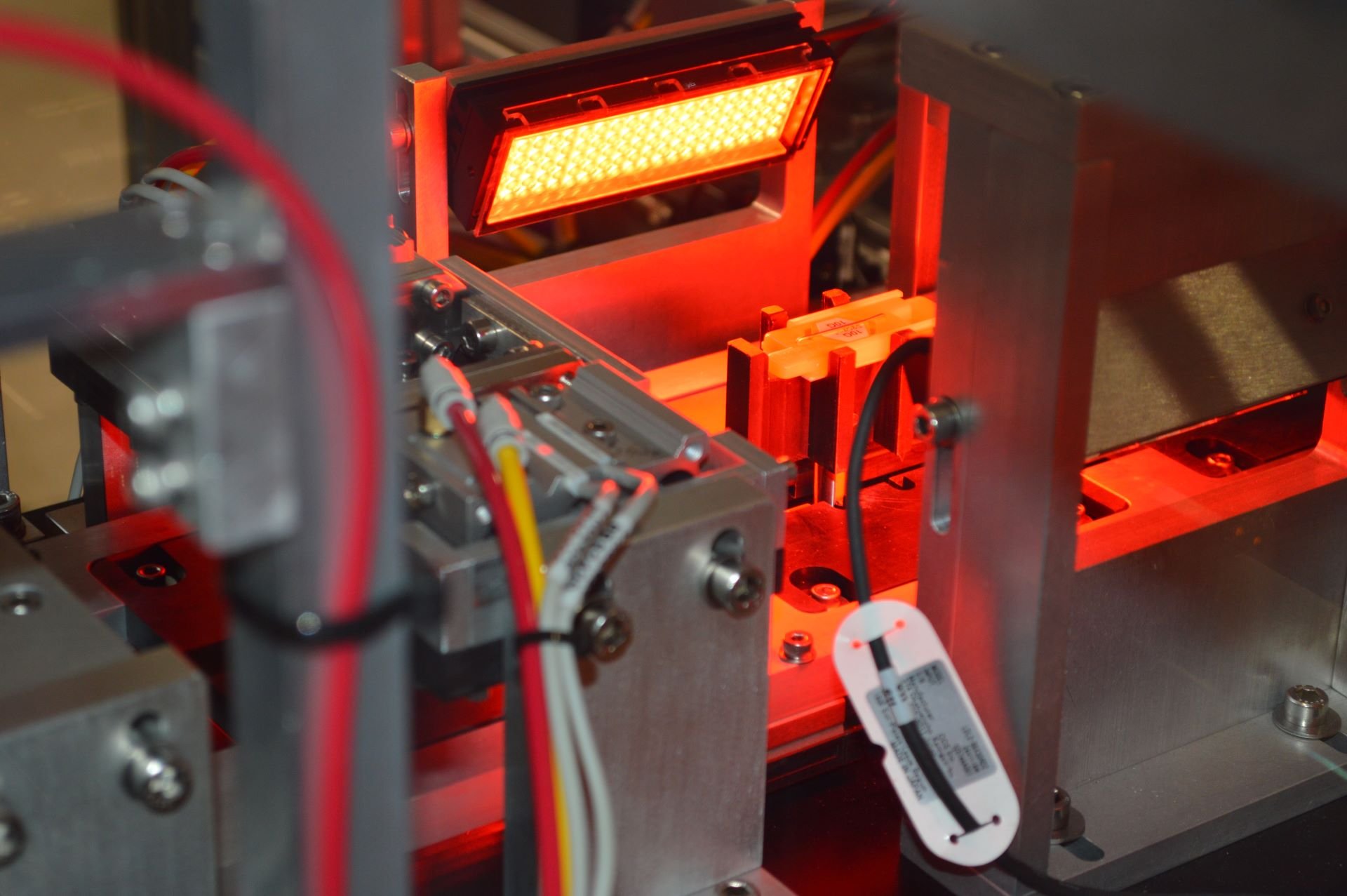

- Quality Control Automation: The system can automate pass/fail functions and material analysis, along with detecting errors in barcodes, colors, or key dimensions and measurements. This saves time and labor while maintaining a superior quality of manufactured goods.

- Testing: A wide range of tests are possible using a visual inspection system, including tests that indicate leaks, defects, contamination, or deformations. They can also perform tests that inform force or torque calibration.

- Data Collection/Manufacturing Execution Systems (MES): Only by monitoring your current productivity and accuracy can you pinpoint areas for improvement. Visual inspection systems provide a constant stream of data, giving you a full picture of where and how you can improve.

- Robot Guidance: Visual feedback can be critical for complicated robotic systems, especially in error detection. Visual inspection systems ensure smooth performance by alerting the machinery to changing conditions.

Benefits

The benefits of adopting visual inspection include:

- Product and procedure improvements based on actual data about errors and waste. This is extremely helpful when manufacturers need to decide whether to cut resources during the process, where the waste is, and what areas of the project require more resources.

- Expense reduction in reducing manual labor. Vision inspection systems generally cost less than a manual inspection, such as hiring someone to do a QC, and are often more accurate in many cases. It has been proven that 100% inspection by people is only 80% effective.

- Real-time data from which to make strategic decisions. Collecting data can take a long time and can slow down your process, especially if you don’t have frequent updates on what’s going on in the plant and how you can fix it.

- 100% inspection rates of all parts. These systems can analyze more of a part than a human can. They can also spot defects that humans can’t quickly catch, such as errors with a barcode.

-1.jpg?width=1920&height=1277&name=DSC_0728%20(4)-1.jpg)

CAPABILITIES

Process Integration Expertise

- Labeling

- Inspection using Vision and Sensors

- Pieces and Part Feeding, Orientation, and Escapement

- Intelligent Motion & Feedback

- Vibratory and Centrifugal Feed Systems

- Web Handling

- Printing

Automated Test, Measurement, Inspection & Calibration Systems

- Calibrating Analyzers for Gas and Material Identification

- Testing and Burn in Cycles for PCB’s

- Inspection Machines using Vision Systems

- Testing Machines that Cycle Product Mechanisms and Measure Performance

Industries We Serve

For over 25 years, we have been successfully designing and building clean sheet, custom solutions for manufacturers all over the world and in many different industries including but not limited to Medical, Pharmaceutical, & Life Sciences, Automotive, Aerospace, Defense, Hi-Tech, and Consumer Products. Some of our areas of expertise include the following: