Capabilities & Services:

Service & Support

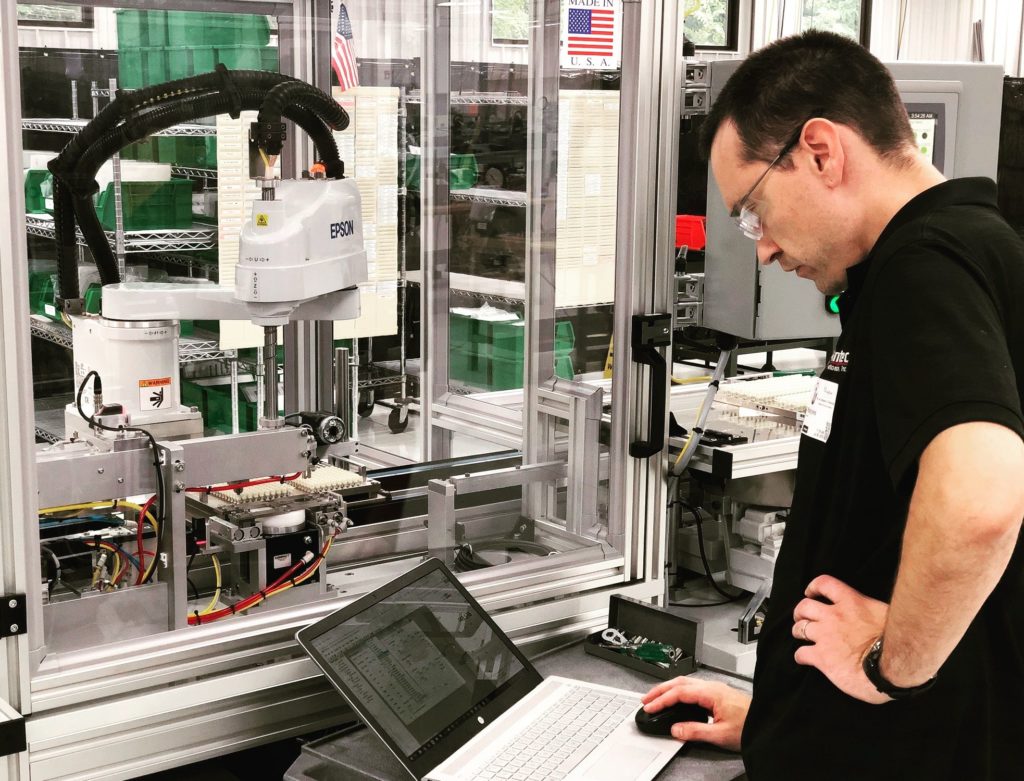

For us, the relationship doesn’t end after installation. We pride ourselves on our reputation for excellent customer satisfaction. We also take pride in the machines we build and the fact that our customers enjoy the benefits of a quality system for many years. We strive to provide the service and support our customers need to make sure their machine gets up and running, and stays that way.

While we build your machine, our technicians and engineers work closely with you to make sure that your final product achieves the results you need. Once the machine is on your floor, installation support and training will continue until everything is up and running according to pre-approved project criteria. And after installation, commissioning, and training, we stand by our work by providing additional support as required.

When you choose Intec, you haven’t just chosen an equipment provider – you’ve chosen a partner.