AUTOMATION SYSTEM:

Medical Device & Kit Assembly

Many of our systems require efficient and unique ways to introduce components into (and out of) the machine. We will provide the best solution for bulk material and component loading and unloading for your automated system.

We have over two decades of expertise with feeding, singulating, orientating, picking and placing, and inspecting products. Some examples include components with different geometries or sizes, needles, medical test kit components, multi-well plates, PCR Tubes, powder, fluid, ball bearings, and more. We will work closely with your team to design and develop the best solution for your application.

CAPABILITIES

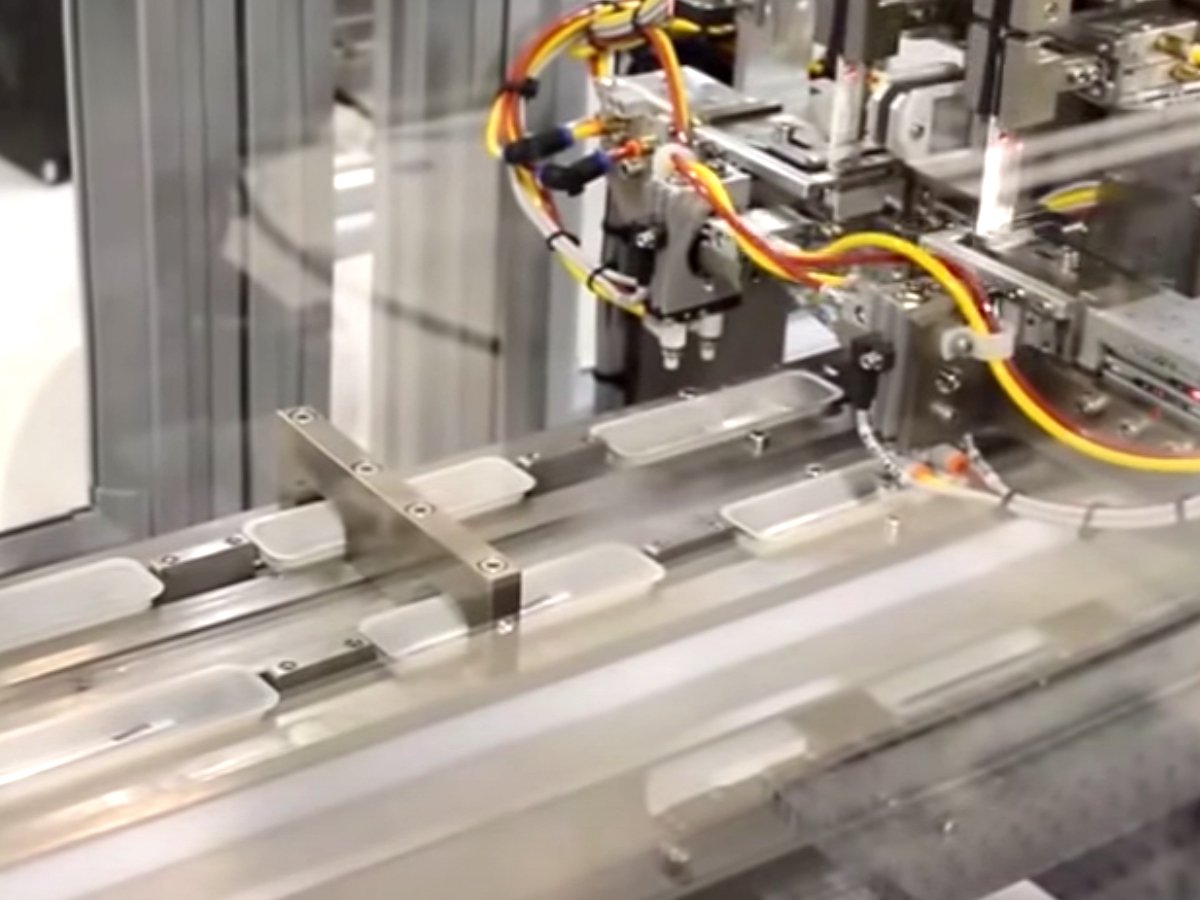

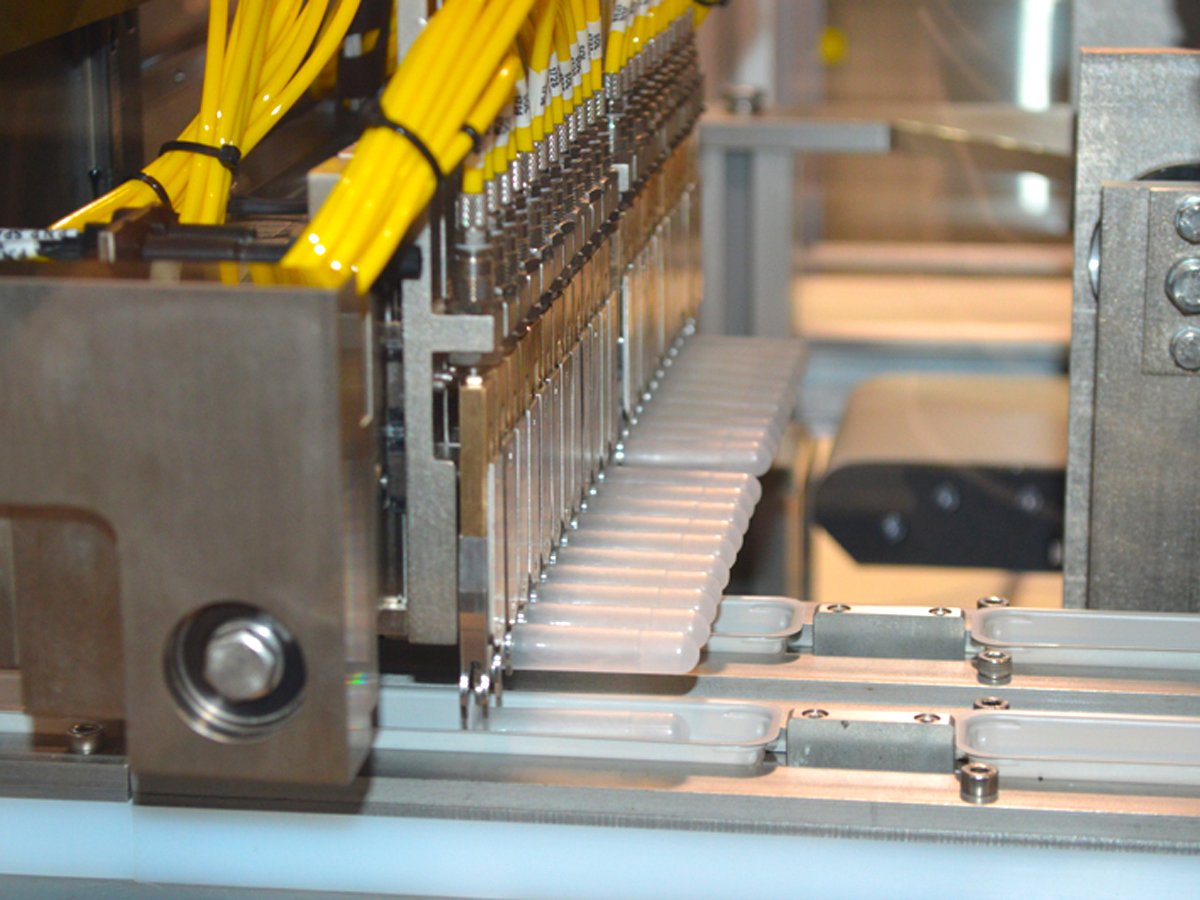

Automated Systems for the Point-Of-Care Diagnostic Testing Field

- Bulk Load and Unload of Multiwell Plates

- Bulk Feed and Pick-And-Place PCR Tubes into Multiwell Plates

- Dispense Fluid at Different Viscosities into PCR Tubes Within Tight Tolerances

- Assemble and Package Test Kits with Test Strips, Desiccant Pouches, Swabs, and Tubes

- Inspect and Confirm Assembly and Processing Steps with Vision Systems

Custom Automation Equipment for Medical Device Assembly

- Suture Forming and Barbing Machines

- Needle Drilling, Welding, Bending, Polishing and Plating Machines

- Patch Lamination and Forming Machines

- Suture Winding Machines

- Syringe Assembly Machines

- Catheter Assembly Machines

- Endoscopic Device Assembly Machines

- Medical Device Cleaning, Gluing and Assembly

- Leak Testing Machines

- Device Inspect & Packaging Machines

Industries We Serve

For over 25 years, we have been successfully designing and building clean sheet, custom solutions for manufacturers all over the world and in many different industries including but not limited to Medical, Pharmaceutical, & Life Sciences, Automotive, Aerospace, Defense, Hi-Tech, and Consumer Products. Some of our areas of expertise include the following:

Automotive

Aerospace

Defense

Hi-Tech

Security

Consumer Products

Packaging

Case Study: Converting a Manual Cannula Forming Process to an Automated Operation

Here is a case study video from a tier-1 medical manufacturer discussing the process of converting their manual cannula-forming process to an automated operation. Intec Automation provided this medical manufacturer with the design, equipment, automation, and build of this project.