Deep Dive: Intec's VP of Engineering Explains the Electronic Circuit Tester

In this video blog, John Weismantel, the Vice President of Engineering at Intec Automation, dives deep into the electronic circuit tester solution....

2 min read

John A. Weismantel

:

Sep 20, 2023 9:00:00 AM

John A. Weismantel

:

Sep 20, 2023 9:00:00 AM

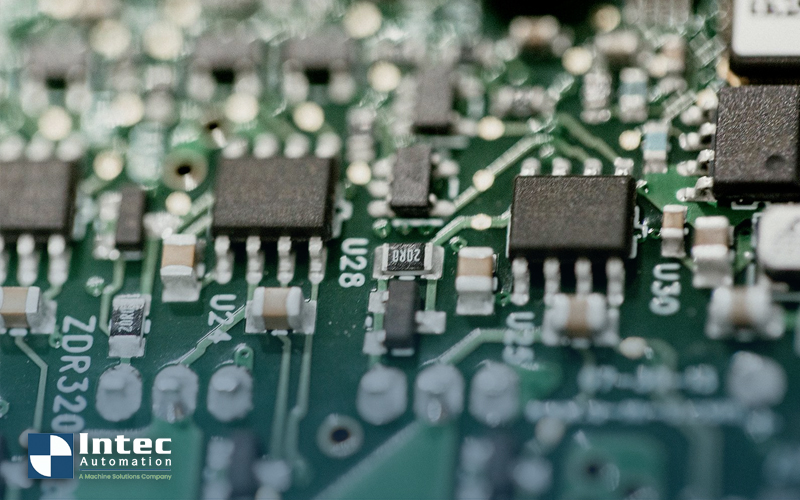

With more sophisticated electronics powering our daily lives, manufacturers that want to automate their assembly operations have to incorporate resistance and HiPot testing into the machine cell. These tests are essential for ensuring product quality but remain a time-consuming process when performed manually.

Most of today’s manufacturers strive for zero out-of-box failures. An acceptable part per million (ppm) failure rate in high-reliability environments at large manufacturers usually has a process capability index (Cpk) of 1.67. That is less than one part per million that fails.

Because circuits are critical to process capability analysis, automating resistance and HiPot testing improves manufacturing reliability, reduces cycle times, and enables a repeatable, compliant, and profitable operation.

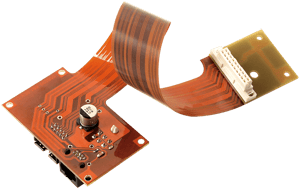

Conductive failures in flexible circuits, wire harnesses, PCB arrays, or battery packs can stem from any number of reasons. Common causes for failing a HiPot or resistance test include defective recipes, contaminants, or damage to an insulation layer.

Conductive failures in flexible circuits, wire harnesses, PCB arrays, or battery packs can stem from any number of reasons. Common causes for failing a HiPot or resistance test include defective recipes, contaminants, or damage to an insulation layer.

Automatically detecting these fault conditions before continuing downstream assembly procedures will:

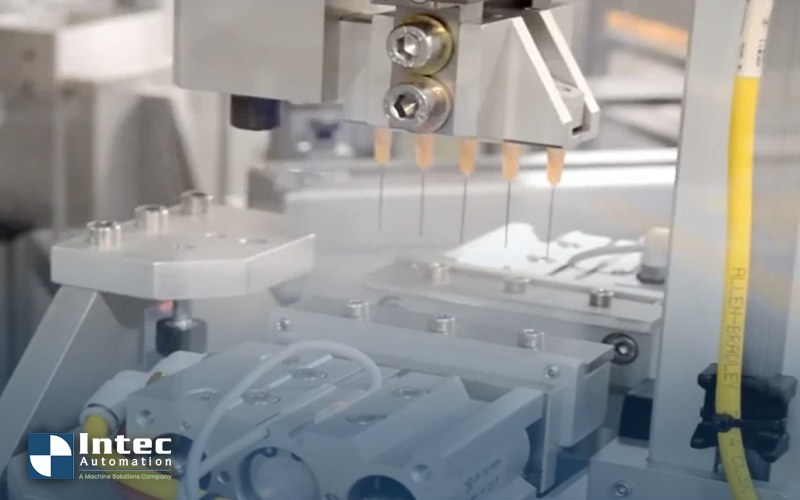

Intec Automation develops automated electronic manufacturing machine cells that include HiPot and resistance testing stations. Our solution incorporates inline vision systems with automated material handling and product manipulation devices that eliminate the need for operators to perform these validations.

Using commercially available HiPot and resistance testing units, Intec integrates test stations with our automated assembly and manufacturing systems. A vacuum conveyor controls the movement of a circuit or panel of circuits as they travel through the different assembly stages. By registering the label of the Device Under Test (DUT), the system can automatically validate it’s the right lot or batch of material and load the required test parameters before starting the procedure.

Using commercially available HiPot and resistance testing units, Intec integrates test stations with our automated assembly and manufacturing systems. A vacuum conveyor controls the movement of a circuit or panel of circuits as they travel through the different assembly stages. By registering the label of the Device Under Test (DUT), the system can automatically validate it’s the right lot or batch of material and load the required test parameters before starting the procedure.

Once the DUT reaches the station, a vision-guided system will locate and register the fiducials on the board to match the contact points with the test unit. A multi-axis gantry keeps the circuit or panel in place before starting the test operation. From here, we can execute the HiPot and resistance tests according to your design and validation requirements. The system will record the outcome of each test, and if necessary, feed any data to the Manufacturing Execution System (MES) for record-keeping purposes.

With this solution, manufacturers can provide demonstrable compliance results for each circuit and automatically reject any that failed, even when they make up part of a circuit array or panel during the breakout process.

The machine cell’s tooling is modular and customizable to accommodate any type of board design. Quick changeovers are built into the solution, allowing manufacturers to switch between different products with limited downtime.

Our automated resistance and HiPot testing capabilities include:

Automation enables you to scale production operations and combine inline inspection systems that reduce labor dependency. Intec Automation delivers innovative solutions that provide precise, consistent, and fast processing of electronic components, medical devices, and other sophisticated products that require a high level of reliability.

To easily see the ROI available from automating your HiPot and resistance test operations, use our new eBook to calculate your potential savings.

In this video blog, John Weismantel, the Vice President of Engineering at Intec Automation, dives deep into the electronic circuit tester solution....

Recent advances in a variety of prophylactic and curative treatments have increased the demand for application specific custom bent or formed needles...

Over the last few decades, contract manufacturing has become an effective business strategy for expanding organizations. However, recent disruptions...