Maintain Tolerances and Eliminate Defects with Automated Cannula Forming

Automation is adding new efficiencies across every manufacturing sector due to a constrained labor market. For medical manufacturers, the growing...

2 min read

Corey Marcotte

:

Mar 19, 2024 8:45:00 AM

Corey Marcotte

:

Mar 19, 2024 8:45:00 AM

Over the last few decades, contract manufacturing has become an effective business strategy for expanding organizations. However, recent disruptions to the global supply chain and labor constraints throughout the manufacturing industry are forcing organizations to rethink their production methods and find a profitable alternative.

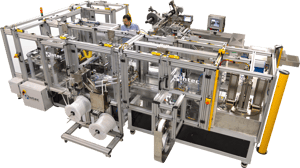

When comparing all available strategies, bringing your manufacturing in-house may be the most profitable way to proceed. OEMs that depend on contract manufacturers have to rely on their expertise to maintain product quality. With an automated machine cell from Intec Automation, you can build quality validation procedures into your manufacturing process while reducing production costs and increasing capacity.

When comparing all available strategies, bringing your manufacturing in-house may be the most profitable way to proceed. OEMs that depend on contract manufacturers have to rely on their expertise to maintain product quality. With an automated machine cell from Intec Automation, you can build quality validation procedures into your manufacturing process while reducing production costs and increasing capacity.

In the past, contract manufacturing was a way to mitigate risk by transferring production responsibilities to a third party. For Repetitive Equipment Manufacturing (REM) organizations, this meant ordering a steady supply of products of equal quality to meet customer demand.

In the past, contract manufacturing was a way to mitigate risk by transferring production responsibilities to a third party. For Repetitive Equipment Manufacturing (REM) organizations, this meant ordering a steady supply of products of equal quality to meet customer demand.

Snap to today and contract manufacturing may increase the risk to your organization as circumstances could change suddenly. Taking control of your production processes with an automated manufacturing solution puts your destiny back in your hands.

With an automated, in-house manufacturing system, you gain:

To ensure you succeed, you should choose an automation partner that will work with you to understand the production requirements and optimize the manufacturing process to develop a solution that provides the best ROI.

By using a collaborative approach, Intec works with customers to define all the manufacturing process requirements and operating parameters. We start with front-end engineering to create a detailed specification and develop the project schedule.

Once the technical specification is approved, we’ll build the custom machine cell and test all operations at our facility. During this phase, we invite customers to attend the start-up and validate all requirements are met with a factory acceptance test (FAT).

Our engineers and technicians will work with your operators to ensure they have the expertise required to run and maintain the system. Intec Automation has experience in complex industries including medical and life sciences, aerospace, automotive, and the defense sectors.

Our engineers and technicians will work with your operators to ensure they have the expertise required to run and maintain the system. Intec Automation has experience in complex industries including medical and life sciences, aerospace, automotive, and the defense sectors.

With an automated manufacturing machine cell from Intec Automation, you can speed up your cycle times, increase production capacity, reduce manufacturing costs, and maintain product quality at all times.

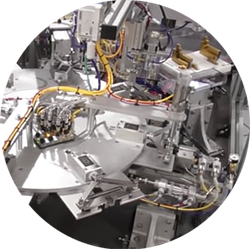

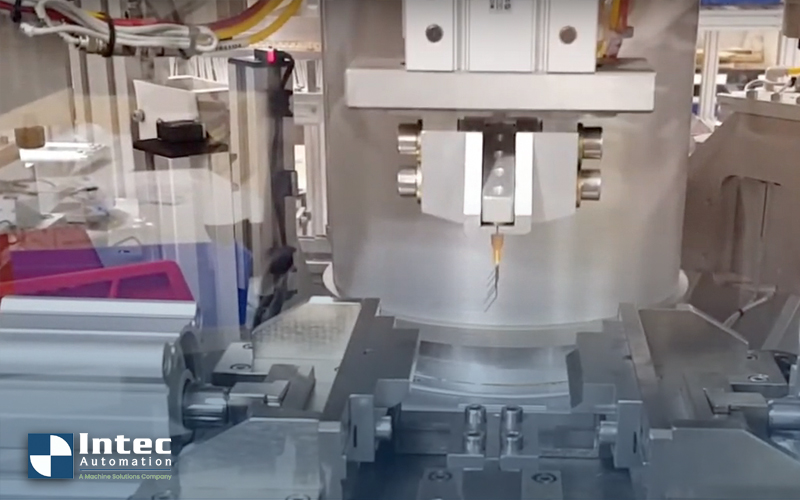

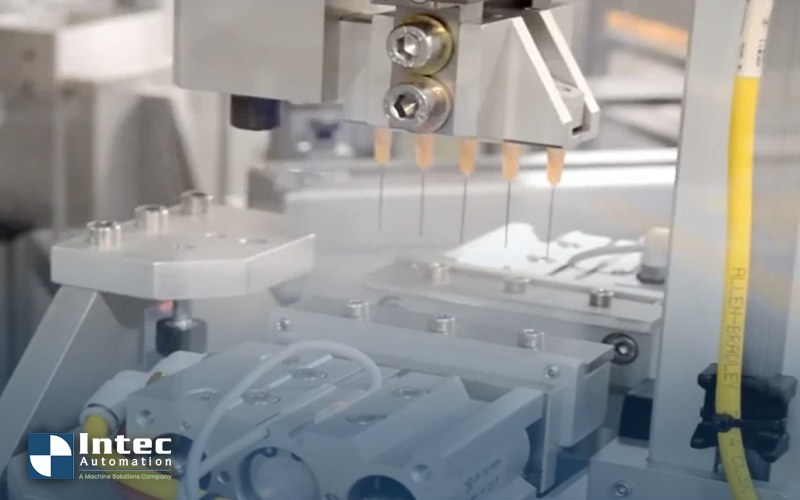

From needle forming and bending systems to medical kit assembly, Intec Automation finds innovative ways to maximize your profitability. Our solutions utilize the latest technologies to create a repeatable and efficient manufacturing process.

If you want to secure your organization’s profitability with an automated manufacturing solution, speak to one of our engineers today.

Automation is adding new efficiencies across every manufacturing sector due to a constrained labor market. For medical manufacturers, the growing...

So, what is the difference between blunt needles and cystotome cannula needles? Blunt Cannula needles are thin, hollow tubes with blunt ends which...

Recent advances in a variety of prophylactic and curative treatments have increased the demand for application specific custom bent or formed needles...