Common Problems & Solutions For Ophthalmic Cannula Forming Operations (Part 2)

In part one of this blog series, here we covered common obstacles with humans vs. automated medical device assemblies. We also covered issues with...

2 min read

John A. Weismantel

:

Feb 14, 2022 4:35:21 PM

John A. Weismantel

:

Feb 14, 2022 4:35:21 PM

Cannulas are small tubes that are primarily used to deliver or extract fluid. They are used in many different industries, with a high percentage being used in the medical field. Medical cannulas are critical to daily operations performed in hospitals, clinics, and research. They are typically disposable, and their high-use nature means that fabrication occurs in large production runs.

There are many different varieties of cannulas, including standardized hypodermic cannulas, and a wide variety of custom cannulas that support an equally broad range of medical and research applications with demanding tolerance requirements. As such, cannulas can vary widely in:

Automating the cannula manufacturing process provides many benefits, including:

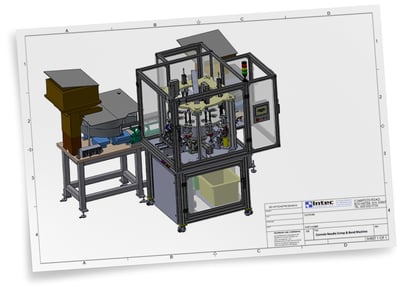

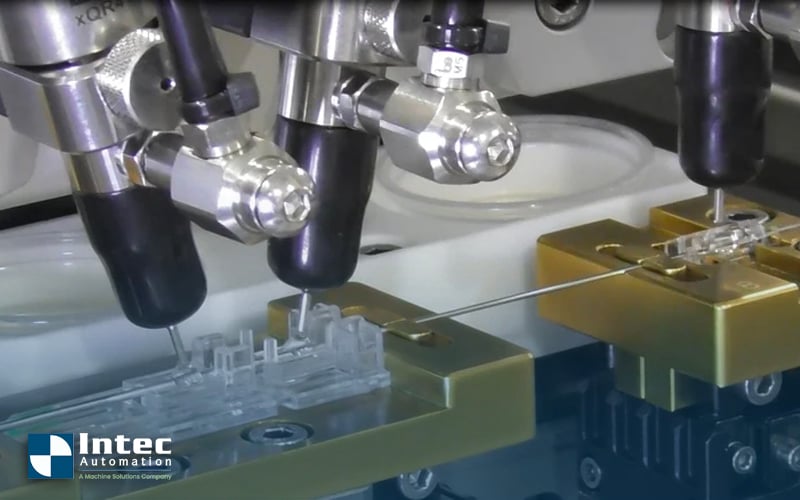

Intec’s Cannula Needle Crimp and Bend Machine gives medical manufacturers the capacity for high-volume cannula production in accordance with a wide variety of customer requirements. Some highlights of the Needle Crimp and Bend Machine include:

Intec’s Cannula Needle Crimp and Bend Machine gives medical manufacturers the capacity for high-volume cannula production in accordance with a wide variety of customer requirements. Some highlights of the Needle Crimp and Bend Machine include:

Here at Intec, we work closely with our customers to ensure they get the best machine for their operation.

Our capabilities include:

We use a variety of feed elements to further enhance production capabilities, such as:

In addition, our machines perform a number of needle assembly and finishing operations, including:

Throughout our processes, we also ensure that there are visual inspection and quality control points along the way to guarantee the final quality of the end product.

We are a world class, custom machine partner. For over 20 years, we have provided customized automation for a wide variety of clients. Our automated processes make mass production more cost-effective for our customers. Moreover, we are a one-stop shop with capabilities for design, fabrication, assembly, programming, testing, debugging, installation, and customer support.

While our primary focus is in the production of medical equipment, we build machines for a wide range of industries. We enjoy long-term relationships with our clients. In fact, over 90% of our business comes from satisfied repeat customers. We offer clean-sheet design and full customization according to the client’s specific needs, and we can automate upstream or downstream.

If you’d like to discuss how Intec Automation can assist you in cannula manufacturing, or to hear about our other customized manufacturing solutions, reach out to us today for more information.

In part one of this blog series, here we covered common obstacles with humans vs. automated medical device assemblies. We also covered issues with...

Matt Bresnahan, Intec’s General Manager, explains the six project stages involved in creating a custom automation solution. He used the example of...

Achieving exact tolerances in micro-dispensing liquid applications is critical for ensuring precision, consistency, and functionality in high-tech...