Achieving Exact Tolerances for Micro-Dispensing Liquid Applications

Achieving exact tolerances in micro-dispensing liquid applications is critical for ensuring precision, consistency, and functionality in high-tech...

2 min read

Corey Marcotte

:

May 2, 2023 11:00:00 AM

Corey Marcotte

:

May 2, 2023 11:00:00 AM

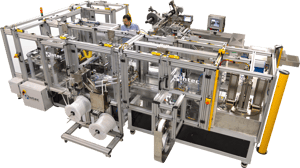

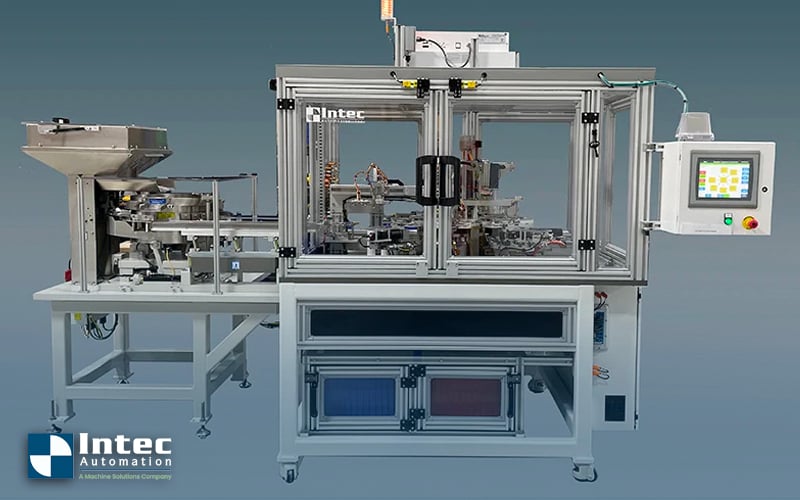

Dispensing machinery is playing an increasingly important role in medical device assembly in the healthcare and life sciences industries. While vendors currently offer manufacturers a variety of single-operation off-the-shelf dispensing machines, meeting the complex and highly specific requirements of the medical and life science industries frequently necessitates custom design for features, such as multiple dispensing heads and variable product lanes.

In these scenarios, manufacturers typically consider long-term growth and scalability before investing in automation solutions to dispensing and product-filling challenges within their facility. At Intec Automation, we provide over two decades of experience in the custom design and manufacture of automated filling and dispensing systems. Consulting with our team of experts, medical and life science manufacturers can set ROI and Overall Equipment Effectiveness (OEE) focused goals for replacing manual and insufficiently automated filling processes with tailored automation equipment to improve quality while reducing downtime and labor costs.

In these scenarios, manufacturers typically consider long-term growth and scalability before investing in automation solutions to dispensing and product-filling challenges within their facility. At Intec Automation, we provide over two decades of experience in the custom design and manufacture of automated filling and dispensing systems. Consulting with our team of experts, medical and life science manufacturers can set ROI and Overall Equipment Effectiveness (OEE) focused goals for replacing manual and insufficiently automated filling processes with tailored automation equipment to improve quality while reducing downtime and labor costs.

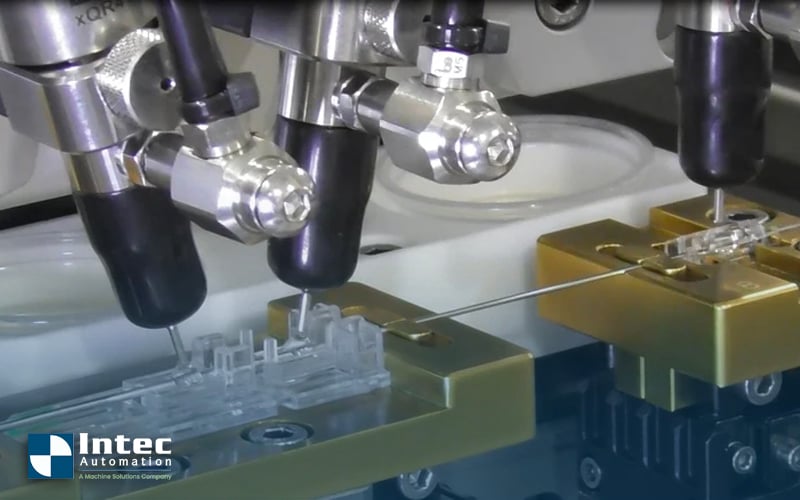

Precision substance dispensing in the life sciences industry comes in a variety of applications. Intec Automation can develop automated dispensing solutions for products of low and high viscosity, as well as different dispensing modes, such as pipettes, positive displacement, and diastolic pumps.

Life science operations that require precision dispensing for low-viscosity, water-like substances include:

Life science operations that require precision dispensing for low-viscosity, water-like substances include:

More viscous products generally comprise of glues and other adhesives. Depending on the medical device in assembly, dispensing equipment may need to handle multiple stages such as two-part epoxy, cyanoacrylates, and/or UV curing adhesives.

Intec Automation solutions for dispensing operations enhance performance quality. Custom dispensing equipment designed, such as precision nozzles and pipettes for specific tasks, introduce a variety of benefits in life science device assembly applications.

Human operators in dispensing systems invariably operate tools inconsistently, varying pressure, time, range of motion, or other input parameters. This variable input reduces product consistency and raises rejection rates. Automating dispensing operations allows manufacturers to reliably create more consistent products at lower costs.

Automated equipment runs at a faster pace than human operators with significantly less downtime.

In healthcare and life science applications such as vaccine vial filling or reagent dispensing, manufacturers must often maintain highly regulated standards of hygiene and isolation. Automated systems reduce the risk of contamination by human operators.

Automated dispensing equipment can operate in a much broader range of facility environmental conditions such as lower temperatures, humidity, and light than preferred by human operators who require specific accommodations for safety and comfort. Over time, automated solutions greatly reduce costs associated with maintaining worker-friendly environmental conditions that machines do not require.

Automated dispensing equipment can operate in a much broader range of facility environmental conditions such as lower temperatures, humidity, and light than preferred by human operators who require specific accommodations for safety and comfort. Over time, automated solutions greatly reduce costs associated with maintaining worker-friendly environmental conditions that machines do not require.

At Intec Automation, our team of experts only offers solutions with demonstrable, long-term ROI. We do the legwork first to understand what our clients need and tailor solutions to unique challenges.

To learn more about what Intec can do, contact us today.

Achieving exact tolerances in micro-dispensing liquid applications is critical for ensuring precision, consistency, and functionality in high-tech...

The clean sheet design and build of custom automated solutions for complex manufacturing applications requires a system integrator with a proven...

Industrial automation is a defining technological trend that covers the entire manufacturing sector. Increased demand for sophisticated products and...