6 Distinct Project Stages: Scaling Your Current Manual Process

Matt Bresnahan, Intec’s General Manager, explains the six project stages involved in creating a custom automation solution. He used the example of...

2 min read

John A. Weismantel

:

Apr 3, 2024 8:00:00 AM

John A. Weismantel

:

Apr 3, 2024 8:00:00 AM

The clean sheet design and build of custom automated solutions for complex manufacturing applications requires a system integrator with a proven process.

Typically, the Intec concept phase starts post-point of sale. This is when we have gathered all the pertinent information and held kickoff meetings with the right people at the table to understand the needs and expectations of the organization fully. Taking this collaborative approach, we develop the right solution from the start to avoid getting “too far” down the engineering path on a solution not tailored to our customer’s needs. Doing this right at the start limits any potential misinterpretations about requirements that could lead to costly changes.

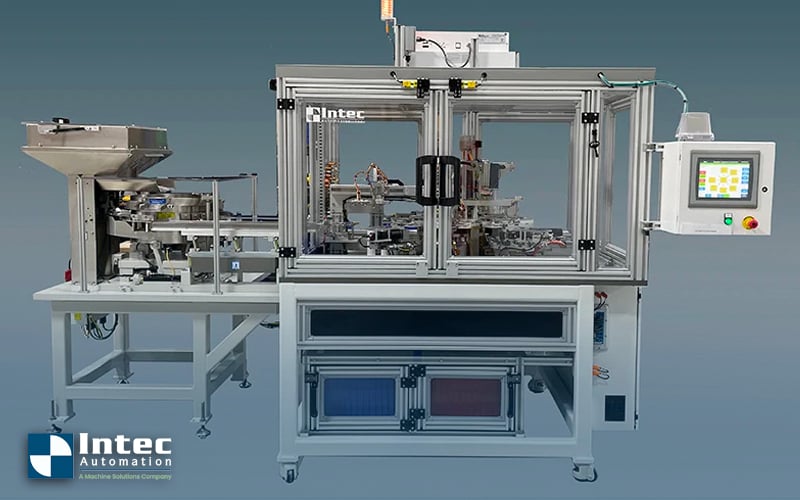

At Intec, we further develop the solution after our concept design review is complete, before proceeding with two additional reviews, namely the preliminary and final design reviews. Through our experience, we know the critical topics to review and resolve at each phase to keep a project on track, in scope, and within budget.

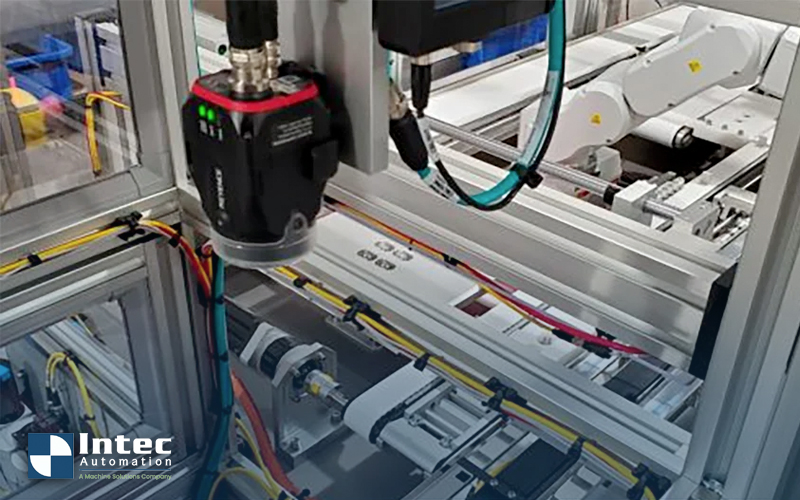

We focus on clean code that is easy to operate and fast to recover if there is a fault for any reason. HMI screens are user-friendly and contain all relevant information for the effective operation of the machine cell. Controls design and HMI examples are reviewed with the customer during the design process to capture any specific requests that can be supported.

It’s your machine and we encourage you to come operate it on our floor. Working with Intec experts who have designed, built, and programmed your investment is the best opportunity for you to learn as much as you can before it arrives on your floor. We welcome customers to bring their operators to Intec for a hands-on experience with our team of experts.

The beauty of our machines is we put them through their paces and test them fully on our production floor before they ship to the customer’s site. After spending time at Intec, many of our customers are capable and confident in their ability to install and start up the equipment, without the need for additional support from Intec. In cases where we are required to assist, Intec is ready to support customers with the installation, start-up, and SAT services performed by our team. We can even bring in international site locations from sister companies to provide local service and support (where needed).

Intec has a dedicated Aftermarket Service and Support specialist ready to answer your call or field a service request. Intec offers options for additional service and support programs post-warranty. These can be custom-designed to support your continued success. Further, as a member of Machine Solutions Inc., Intec has access to global service sites that allow us to meet your needs promptly.

Matt Bresnahan, Intec’s General Manager, explains the six project stages involved in creating a custom automation solution. He used the example of...

After a few years of turmoil, analysts now have a positive outlook on the US manufacturing sector. Supply chains are stabilizing and new production...

Cannulas are small tubes that are primarily used to deliver or extract fluid. They are used in many different industries, with a high percentage...