INTEC OFFERS TURNKEY MACHINE BUILDING

Intec Automation offers turnkey services for its machine building capabilities from collaborating with customers on the best concept of the project...

2 min read

Dane Mooers

:

Feb 14, 2022 5:07:02 PM

Dane Mooers

:

Feb 14, 2022 5:07:02 PM

The COVID-19 pandemic has caused major interruptions to business operations within countless industries. As a result, many companies are looking for solutions that both improve their current situation and increase their resilience when faced with unforeseen circumstances in the future. In the manufacturing sector, a key focus is assembly automation. According to a survey conducted by ASSEMBLY magazine, 32% of all assembly plants in the United States and 44% of medical device manufacturers will spend more on assembly technology in 2021 compared to the previous year. It is highly likely that a significant portion of these investments will be directed towards automation since it is a cost-effective way for businesses to increase production speed without sacrificing quality.

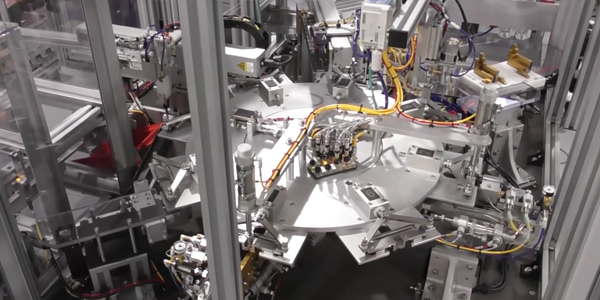

At Intec Automation, Inc., we are a premier source of custom industrial automated machinery and production systems. Throughout the years, we’ve expanded our automation solutions to better meet the demands of our customers. We currently offer automation equipment that integrates a range of high-reliability hardware, including robots, conveyors, vibratory bowls, vision components, and electrical/control systems.

Manual systems are generally simpler than automated systems, which makes them easier to implement. Additionally, they are more suitable for highly complex tasks (e.g., testing operations that involve complicated features) and more sustainable for certain tasks (e.g., testing operations that require human feedback). However, in basic operations, they are slower than automated systems. They are also more prone to error. As a result, they often prove to be more expensive in the long run.

In contrast, automated systems are extremely cost-effective when used in the right applications. They can reduce the amount of human labor needed for time-consuming, repetitive tasks, which frees up workers to focus on ones that require higher-level decision-making. Additionally, they minimize the risk of human error, which decreases resource waste. Automated systems are best suited for simple tasks that do not require human feedback.

In contrast, automated systems are extremely cost-effective when used in the right applications. They can reduce the amount of human labor needed for time-consuming, repetitive tasks, which frees up workers to focus on ones that require higher-level decision-making. Additionally, they minimize the risk of human error, which decreases resource waste. Automated systems are best suited for simple tasks that do not require human feedback.

Integrating automation technology into assembly operations can benefit a manufacturer in many ways, including the following:

In turn, all of these benefits can lead to an improved bottom line for the company.

A company can achieve a good return on investment (ROI) when the automated system is implemented properly. Factors used to calculate the success of an automation solution can be classified into two categories: soft and hard.

A company can achieve a good return on investment (ROI) when the automated system is implemented properly. Factors used to calculate the success of an automation solution can be classified into two categories: soft and hard.

Indirect ROI metrics are more difficult to measure since they are not as quantifiable in numbers. They may include:

Direct ROI metrics are easy to quantify in numbers. They may include:

We partner with some of the most highly respected names in equipment manufacturing to ensure our automation solutions use the best components. As a result, customers can trust our machines and systems to operate and perform as intended. Our equipment manufacturer partners include Rockwell Automation, Keyence, Cognex, Siemens, Epson, Mitsubishi, FANUC Automation Systems, and more.

Automation technology enables businesses to streamline their operations—especially those involving highly repetitive, simple tasks—so they can improve their productivity and profitability. The experts at Intec are fully aware of these and other potential benefits, which is why we aim to provide customized turnkey automation solutions for even the most challenging manufacturing, development, and assembly needs.

Intec has delivered industrial automation solutions to customers across a wide range of industries for over 20 years. This extensive experience enables us to design and build quality systems that allow the companies we serve to achieve ROI within an average of one to two years.

The types of automation systems we offer include:

To learn more about our automation solutions and how they can benefit your company, contact us today.

Intec Automation offers turnkey services for its machine building capabilities from collaborating with customers on the best concept of the project...

Automation can save countless dollars in manufacturing costs as well as improve overall quality and efficiency of your process, therefore increasing...

With its deep-rooted foundation of over two decades of experience in factory automation, specialty equipment and clean-sheet design and build of...