AUTOMATION SYSTEM:

Precision Needle-Bending Equipment

for Medical Manufacturing

Cannulas, cystotomes, biopsy tools, and other medical devices often require needles formed to exact specifications. Meeting that demand at scale calls for more than operator skill. Intec designs automated bending systems that deliver consistent results across gauges, angles, and production volumes.

The Limits of Manual Bending

Operators working with jigs or semi-automated presses face the same set of problems: inconsistency, fatigue, and time lost to setup. Changing gauge size or bend angle often forces operators to reset equipment. That step interrupts production and adds the risk of scrap. In industries where every part must meet strict validation requirements, even small inefficiencies create real cost. Automated bending replaces operator judgment with controlled, repeatable motion, so every cycle delivers the same geometry.

How the System Works

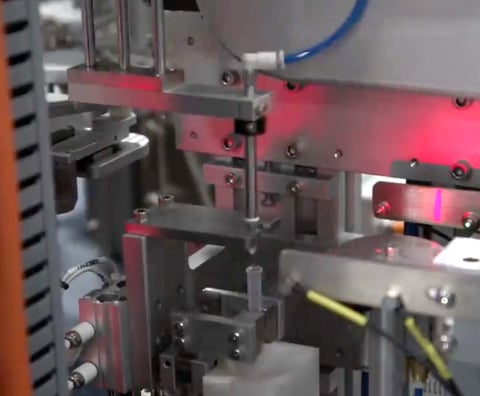

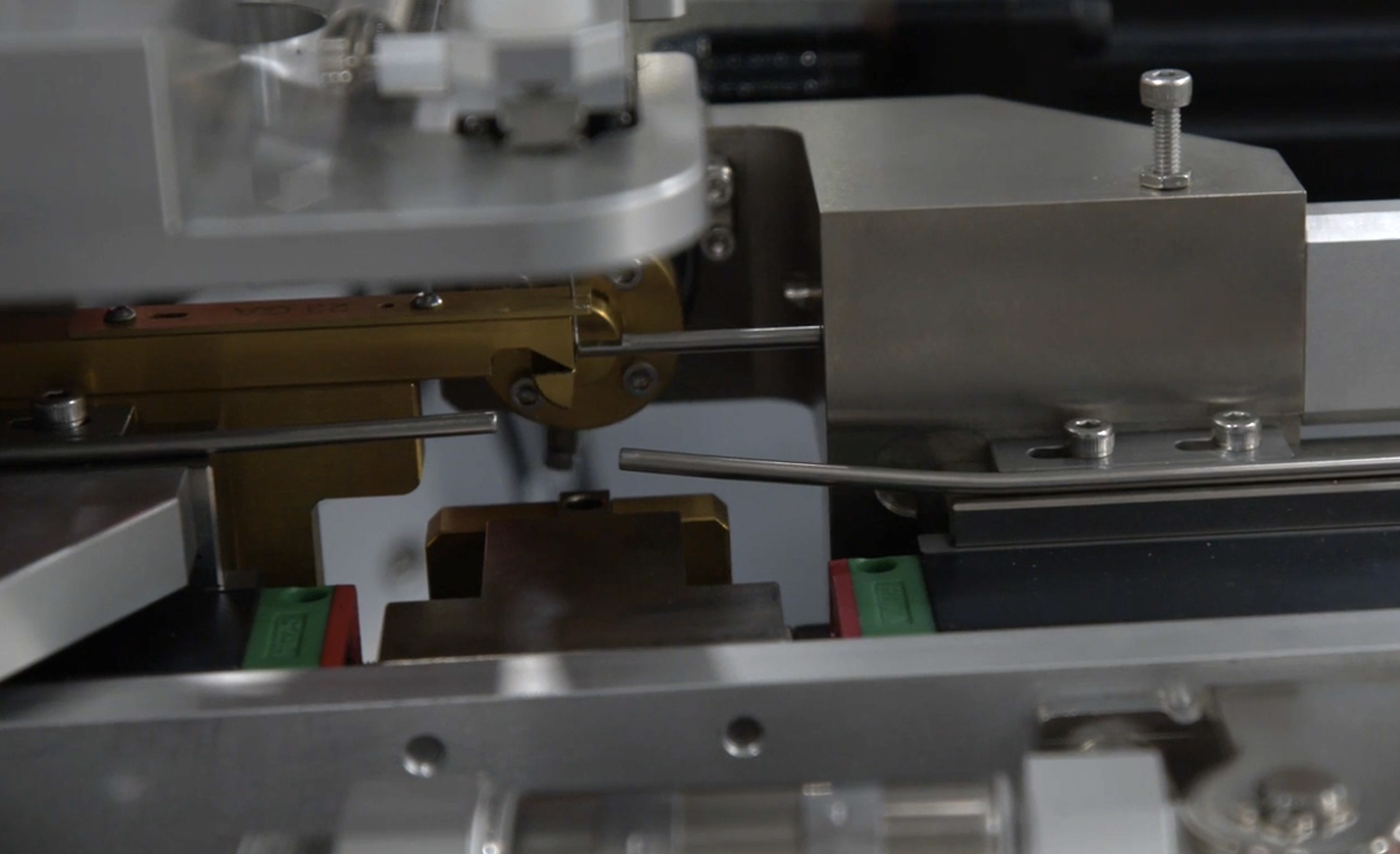

Intec’s needle-bending machines are built for controlled flexibility. Servo actuators position forming tools with exact offsets, while a vertical drive sets the insertion depth, all of which are managed through HMI recipes. Updating the recipe is enough to shift from a 45° bend at 6 mm to a 60° bend at 4 mm. No tooling change required. Springback can be corrected in real time when raw material temper shifts.

Intec’s needle-bending machines are built for controlled flexibility. Servo actuators position forming tools with exact offsets, while a vertical drive sets the insertion depth, all of which are managed through HMI recipes. Updating the recipe is enough to shift from a 45° bend at 6 mm to a 60° bend at 4 mm. No tooling change required. Springback can be corrected in real time when raw material temper shifts.

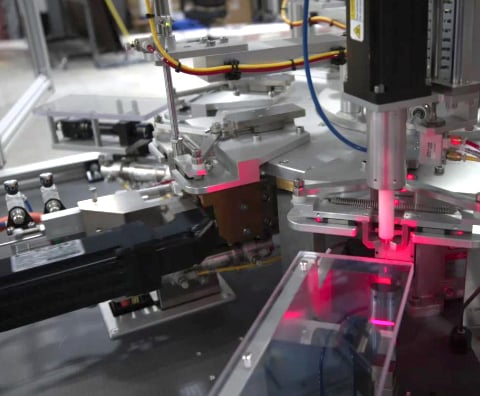

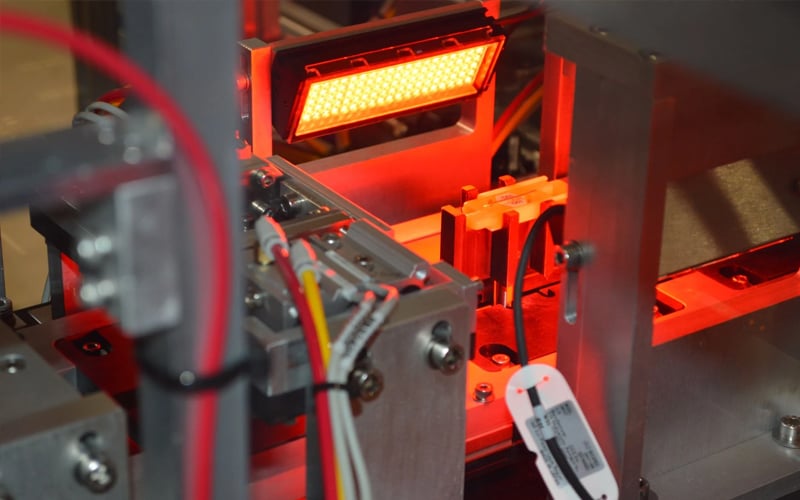

Automation continues beyond forming. Vibratory feeders and robotic pick-and-place deliver needles to a rotary transfer platform that handles sheathing removal, bending, crimping, re-sheathing, inspection, and offloading in one cycle. A programmable logic controller (PLC) enclosure coordinates every motion for high-speed precision.

Prototyping starts with soft tooling to form and measure samples before transitioning to hardened tools for production. Complex geometries that involve multiple bends are handled with recipe-specific tooling, designed to repeat the same motions with exact offsets each cycle. Vision modules can be integrated at the next station to measure bend angles and orientation in-line, giving engineers immediate confirmation that each part meets specification and limiting the need for additional downstream checks.

Benefits for Production Teams

Consistent Accuracy

Across gauges from 12 to 30, the systems hold tolerances to the micron. That level of precision keeps production aligned with the strict requirements of medical device manufacturing.

Faster Changeovers

Instead of hours lost to tooling swaps, recipe updates handle gauge or angle adjustments in minutes. Operators spend less time resetting and more time running parts.

Prototype to Production

Soft tooling makes it easy to trial new designs and collect data before committing. Once hardened tools are in place, the same recipes carry forward for long-term use.

Integrated Quality Control

Machine vision adds real-time verification to the process, reducing defects and protecting yield.

Streamlined Operations

Self-contained systems reduce reliance on multiple stations by combining feeding, forming, inspection, and offloading into one continuous flow.

Modular, Customizable Design

From cart height to shelf spacing to nest layout, the AutoRacker is built to be flexible and customized; the units are designed to be scalable across product lines and process types.

Applications Across Medical Manufacturing

Needle-bending systems are already at work in some of the most demanding sectors of healthcare manufacturing.

Cannula and cystotome needles require extremely small bends, sometimes as little as a half-millimeter at ninety degrees, that must be formed without distortion. Automated bending makes sure those features are consistent across every batch.

Biopsy and surgical tools often incorporate multiple bends and precise orientations to meet clinical requirements. Recipe-specific tooling handles these complex geometries without sacrificing throughput.

Drug-delivery devices rely on repeatable bends for safety and performance. Servo-driven positioning makes it possible to adjust quickly for different gauges and lengths without downtime.

Cannula bending and crimping has become one of the most requested applications, with dedicated Intec machines feeding, forming, and sheathing assemblies as a turnkey process. The demand is growing so rapidly that these machines are becoming a standard platform in Intec’s lineup.

Built for the Realities of Manufacturing

Medical device manufacturers face constant pressure to increase output while maintaining compliance. Intec’s systems are engineered with that reality in mind. From cycle times tuned to production targets to recipe libraries that support dozens of SKUs, the equipment is designed to minimize downtime and maximize yield. Because design, fabrication, and control integration are all completed in-house, delivery times are short; one recent build moved from engineering to factory acceptance in just 20 weeks.

Start the Conversation

The demand for advanced medical devices will only grow. Meeting it requires equipment capable of forming precise geometries at scale without compromise. Intec’s needle-bending systems give manufacturers the accuracy, speed, and reliability they need to stay ahead.

Contact Intec Automation today to discuss how our team can support your next needle-bending project.