AUTOMATICALLY ASSEMBLING, INSPECTING, AND BENDING CYSTOTOME NEEDLES

Manual assembly/bending of Cystotomes is very common in low-med. volume production, however this comes with many challenges as the process requires a...

2 min read

John A. Weismantel

:

Oct 28, 2025 8:00:02 AM

John A. Weismantel

:

Oct 28, 2025 8:00:02 AM

Manual steps remain common in diagnostic device assembly, but they often create more challenges than benefits. High output requirements and strict quality standards make the limits of manual handling even more visible.

Diagnostic device assembly often depends on people moving, placing, and dispensing parts by hand. Operators can handle delicate work, but the approach brings fatigue and inconsistency into the process. Repetition across long shifts increases the likelihood of small mistakes, while constant attention to fine details can wear down focus. As devices grow more complex, the chance of contamination, mistakes, and production slowdowns increases.

Manual handling introduces variability at nearly every stage of assembly. Some operations still rely on batch sub-assembly, where parts are grouped and passed along between workers. This method slows production and allows errors to multiply before detection. Even when a one-piece flow approach is used, balancing cycle times between operators is difficult. Productivity often depends on the speed and focus of a single individual.

Manual handling introduces variability at nearly every stage of assembly. Some operations still rely on batch sub-assembly, where parts are grouped and passed along between workers. This method slows production and allows errors to multiply before detection. Even when a one-piece flow approach is used, balancing cycle times between operators is difficult. Productivity often depends on the speed and focus of a single individual.

Common drawbacks of manual handling include:

In diagnostic devices, a single slip (like mislabeling a part or dispensing the wrong reagent) can compromise the product. At high volumes, even a small error repeated across thousands of units creates major losses.

Certain jobs are especially tough to manage by hand. These are the first to automate:

Certain jobs are especially tough to manage by hand. These are the first to automate:

Replacing these steps with automated systems removes variability and creates a steadier production flow.

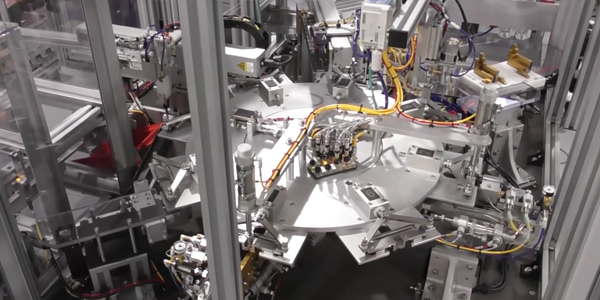

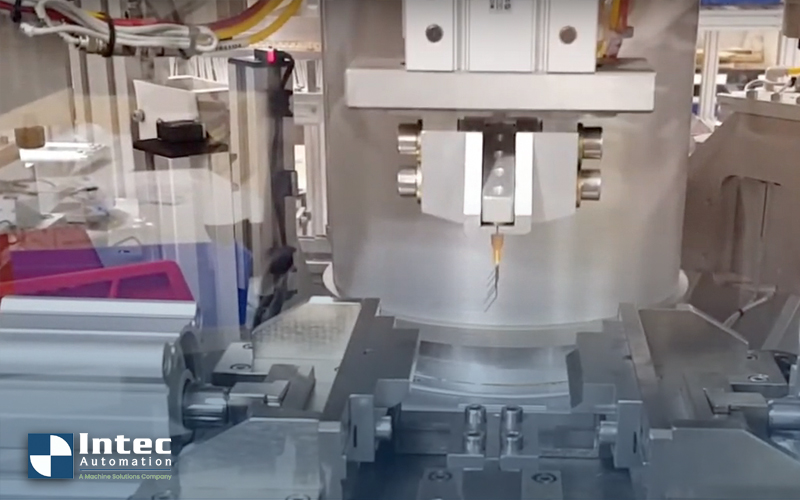

Several proven automation technologies support diagnostic device assembly:

Together, these systems create a streamlined, controlled process that improves accuracy, reduces reliance on operators, and stabilizes throughput.

Automated lines support true one-piece flow. Defects are flagged before more labor or material goes into them, which reduces waste. Cycle times even out, output climbs, and more product ships without adding extra shifts. For companies facing high labor costs or constant turnover, automation keeps production moving without the burden of nonstop training.

Minimizing manual handling in diagnostic device assembly is a direct path to higher productivity and stronger product quality. By applying automation strategically, manufacturers reduce risk while unlocking performance gains that manual processes cannot sustain.

Intec Automation designs and integrates these solutions with the expertise required to keep operations competitive. Contact us today to get started!

Manual assembly/bending of Cystotomes is very common in low-med. volume production, however this comes with many challenges as the process requires a...

Automation is adding new efficiencies across every manufacturing sector due to a constrained labor market. For medical manufacturers, the growing...

Matt Bresnahan, Intec’s General Manager, explains the six project stages involved in creating a custom automation solution. He used the example of...