Needle-Bending Equipment Solutions for Medical Manufacturers to Minimize Downtime

Recent advances in a variety of prophylactic and curative treatments have increased the demand for application specific custom bent or formed needles...

2 min read

Greg Clark

:

Feb 11, 2022 3:39:13 PM

Greg Clark

:

Feb 11, 2022 3:39:13 PM

So, what is the difference between blunt needles and cystotome cannula needles? Blunt Cannula needles are thin, hollow tubes with blunt ends which are utilized for a variety of medical applications, such as wound irrigation, administering medicine, and precision fluid dispensing. Because these needles have blunt tips, they cannot readily pierce through skin; they require another sharp needle or tool to create an entry point. While cannulas are made from a number of materials, one of the most commonly used is stainless steel.

Cystotome cannula needles have sharp tips, which enable them to create their own entry points. Cystotome cannula needles are typically used for fluid and drug delivery, puncturing, piercing, scraping, and precision surgical cuts. Cystotome needles are commonly used in many different surgical procedures, including ophthalmic procedures, in which the needles are bent to a particular angle or radius to conform with the convexity of the crystalline lens to assist the physician in surgery.

Cystotome cannula needles have sharp tips, which enable them to create their own entry points. Cystotome cannula needles are typically used for fluid and drug delivery, puncturing, piercing, scraping, and precision surgical cuts. Cystotome needles are commonly used in many different surgical procedures, including ophthalmic procedures, in which the needles are bent to a particular angle or radius to conform with the convexity of the crystalline lens to assist the physician in surgery.

Cannula needles are manufactured by gluing straight lengths of different gauge tubular steel into luer locking hubs. The assembled needles are then bent to the desired bend angle or radii.

Manual cystotome needle bending operations typically proceed as follows:

The maximum yield of the manual process is less than 400 finished units per hour.

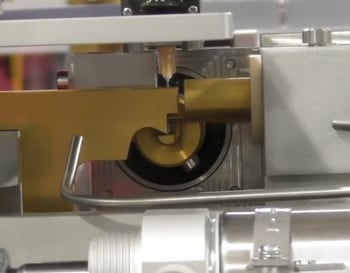

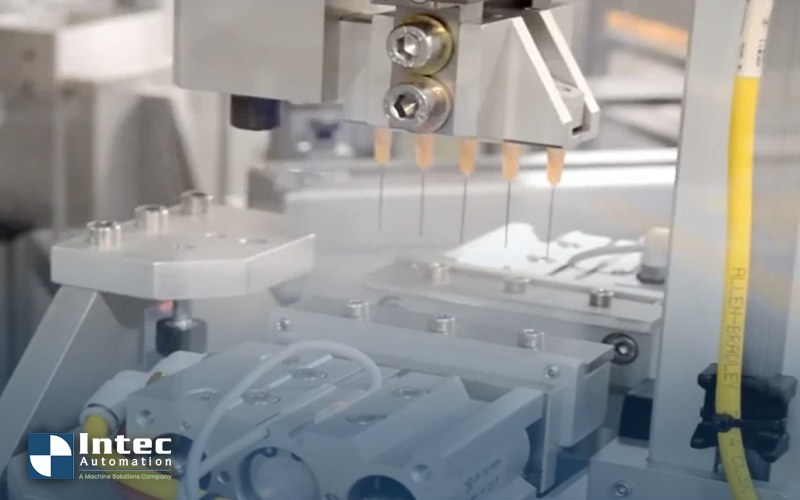

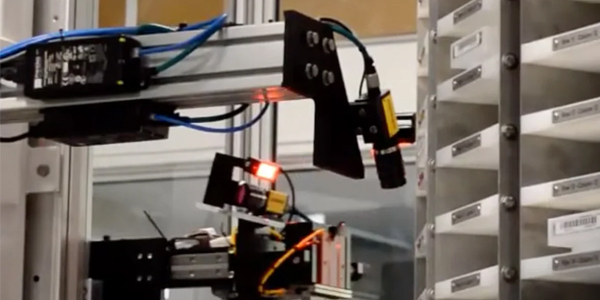

Manual cystotome bending operations are slow and tedious, with varying results. The operator is also at risk while manually handling the sharp needles. Intec’s development of automated cystotome needle bending machines has enabled bending operations to increase in throughput, while enhancing overall product quality. The machines use automation technology to infeed needle blanks with their protective sheaths, remove the sheath, orientate the needle/tip to the desired position, bend the needle to the required angle or radius, inspect the bend with a vision quality control system, replace the sheath, and outfeed the completed product into a bulk bin. Automation systems help cannula needle manufacturers and resellers increase their production capacities and improve overall product quality.

Intec Automation has decades of experience designing and building automated needle bending machines and can accelerate bending operations by a minimum of 8-10 times the manual throughput, with one automated system, which will produce in excess of 3,600 finished parts per hour.

In addition to faster production, automated bending machines can utilize vision inspection to quickly assess multiple features and checks, including:

KEY ADVANTAGES OF AUTOMATED NEEDLE BENDING MACHINES

Intec Automation has decades of expertise with automating needle bending, forming, and crimping, including but not limited to surgical needles, drilling needles, blunt cannulas, cystotome needles, and more. Intec is committed to providing innovative custom automation systems that help customers achieve and exceed their production objectives. To learn more, contact us today at sales@intecautomation.com.

Recent advances in a variety of prophylactic and curative treatments have increased the demand for application specific custom bent or formed needles...

Over the last few decades, contract manufacturing has become an effective business strategy for expanding organizations. However, recent disruptions...

Product failures borne from low-quality design or inadequate manufacturing processes are simply unacceptable for medical device OEMs. The liabilities...