The Importance of Selecting The Right Automation System & Partner

Automation can save countless dollars in manufacturing costs as well as improve overall quality and efficiency of your process, therefore increasing...

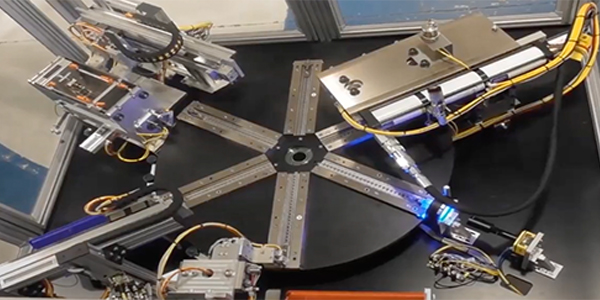

Precision tube flaring has increased beyond many companies’ manual capabilities due to an increase in soft tissue biopsies, more elective surgeries, and an increase in both the automotive and aerospace industries.

With the increased demand, automation is being considered as a viable option to keep up production due to the consistent output and the integrated quality control features, such as precision distance and force.

Additionally, integrated intelligent vision systems can detect cracks and defects from the flaring process typically missed by the human eye. Intec has over 20 years of experience in the automation industry with expertise in thin-walled SS tubes that vary in length and diameter. Intec has designed and built precision flaring equipment with real-time visual quality control systems for various industries, including but not limited to Medical, Life Sciences, Automotive, and Aerospace. Please contact us today for your tube and/or cannula flaring needs.

Automation can save countless dollars in manufacturing costs as well as improve overall quality and efficiency of your process, therefore increasing...

Custom automation success goes beyond specs and software; it comes down to choosing the right people. The right integrator helps you avoid delays,...

Sub-assembly and Assembly operations can be very labor-intensive or redundant and can create bottlenecks. Identifying these types of tasks is the key...