Maintain Tolerances and Eliminate Defects with Automated Cannula Forming

Automation is adding new efficiencies across every manufacturing sector due to a constrained labor market. For medical manufacturers, the growing...

1 min read

Corey Marcotte

:

Feb 14, 2022 4:43:58 PM

Corey Marcotte

:

Feb 14, 2022 4:43:58 PM

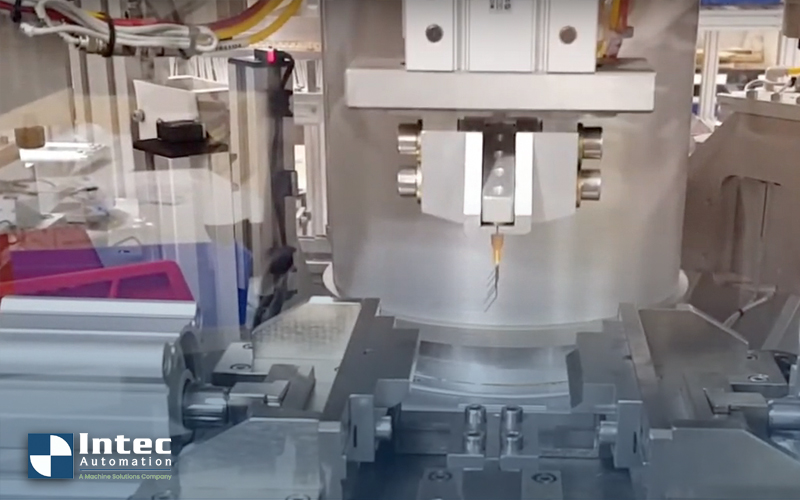

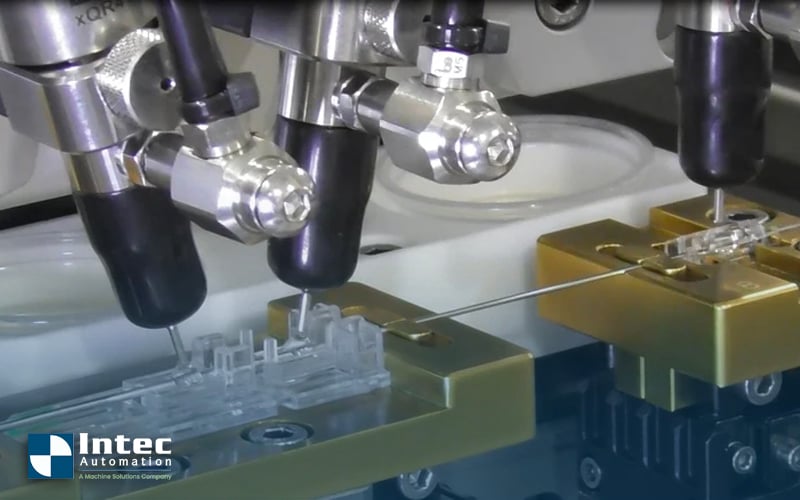

Manual assembly/bending of Cystotomes is very common in low-med. volume production, however this comes with many challenges as the process requires a highly skilled operator to place individual needles under magnification, properly orientate the tip position and angle, and manually bend the needle blank to the specific angle or radius.

This is a time-consuming and tedious process, which in the end produces an inconsistent finished product with a high production cost. Additionally, the pre-sharpened cystotome needles pose a real safety hazard to the operators and present a liability challenge for many companies.

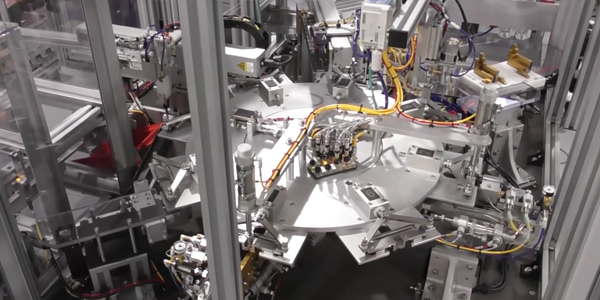

Intec has developed precision servo and vision-guided solutions to guarantee consistent high-quality needles with increased throughput. We have extensive experience feeding sheathed and non-sheathed needles, removing and replacing protective sheaths, orientating pre-sharpened needles with industrial vision systems, bending needle tips, bending angles and radii, re-sheathing bent needles, and out-feeding finished product.

Contact us today. We can help your company improve both the throughput and quality of your needle manufacturing process.

Automation is adding new efficiencies across every manufacturing sector due to a constrained labor market. For medical manufacturers, the growing...

Achieving exact tolerances in micro-dispensing liquid applications is critical for ensuring precision, consistency, and functionality in high-tech...

It's critical to ask the right questions when searching for a partner to help you automate manufacturing processes in the medical and life sciences...