Medical Device OEMs: How to Ensure Zero Out-of-Box Failures

Product failures borne from low-quality design or inadequate manufacturing processes are simply unacceptable for medical device OEMs. The liabilities...

1 min read

Matthew Bresnahan

:

Apr 18, 2024 10:00:00 AM

Matthew Bresnahan

:

Apr 18, 2024 10:00:00 AM

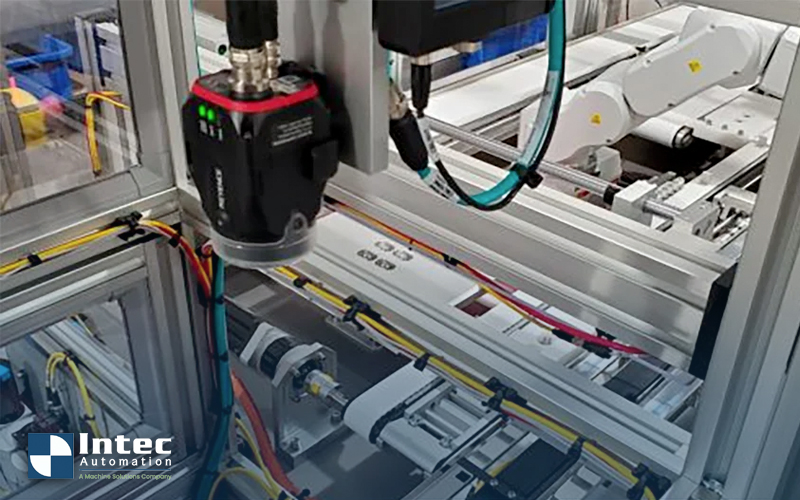

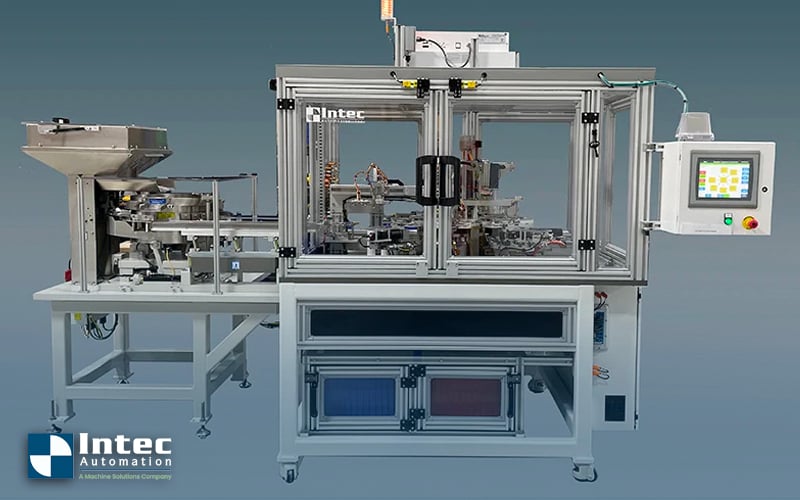

Out-of-box failures can stem from a myriad of factors. For bent needles or cannulas, the geometry of the final product has to conform to the exact dimensions required for its intended use. Similarly, process parameters can be sensitive to variations in temperature and humidity (especially when it comes to filling or dispensing exact volumes). Poorly maintained machines, environmental factors, and human operators can contribute to out-of-box failures.

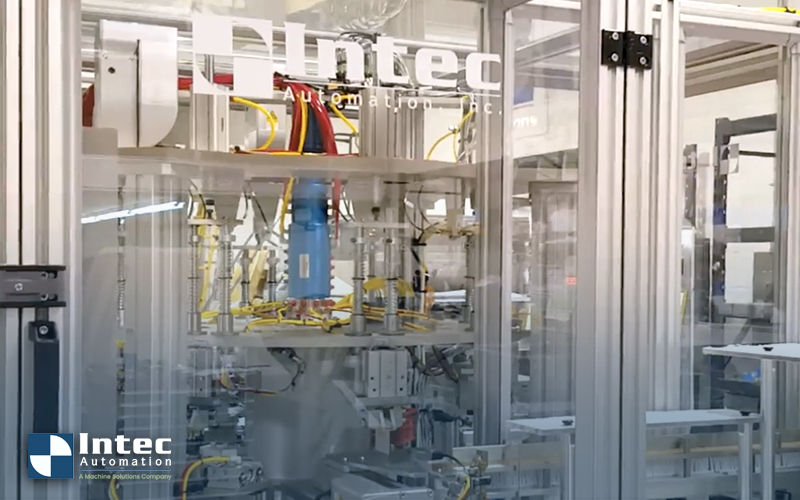

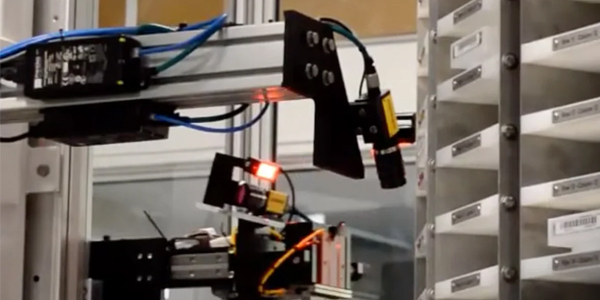

Controlling each of these variables across batches requires extensive quality control measures that detect and intervene when products pass through different assembly stations.

These solutions can integrate with a robust machine design that addresses each of the quality checks required during manufacturing. Automated reject functions can remove defective raw materials or products as they fail to eliminate added additional downstream value and only allow compliant devices to leave the line.

Product failures borne from low-quality design or inadequate manufacturing processes are simply unacceptable for medical device OEMs. The liabilities...

After a few years of turmoil, analysts now have a positive outlook on the US manufacturing sector. Supply chains are stabilizing and new production...

The clean sheet design and build of custom automated solutions for complex manufacturing applications requires a system integrator with a proven...