Needle-Bending Equipment Solutions for Medical Manufacturers to Minimize Downtime

Recent advances in a variety of prophylactic and curative treatments have increased the demand for application specific custom bent or formed needles...

3 min read

John A. Weismantel

:

Jun 25, 2024 8:30:00 AM

John A. Weismantel

:

Jun 25, 2024 8:30:00 AM

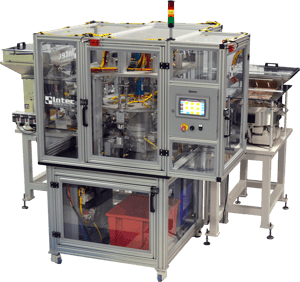

Widely used in the medical field for surgery or in optometry, cannula manufacturing assembly can vary greatly with the needle length, geometry, gauge, and material requirements. There are hundreds of permutations to cannula processing so when you are thinking about automating your current cannula operations, there is a great need for flexible manufacturing solutions to produce these high-quality products.

Finished cannula products must also meet demanding tolerance requirements and are subject to multiple inspections during the production process so it’s important to find an automation partner with experience in this manufacturing operation. Ultimately, the ability to automate this process enables a more consistent, reliable product while also allowing you to increase output, reduce downtime and labor requirements.

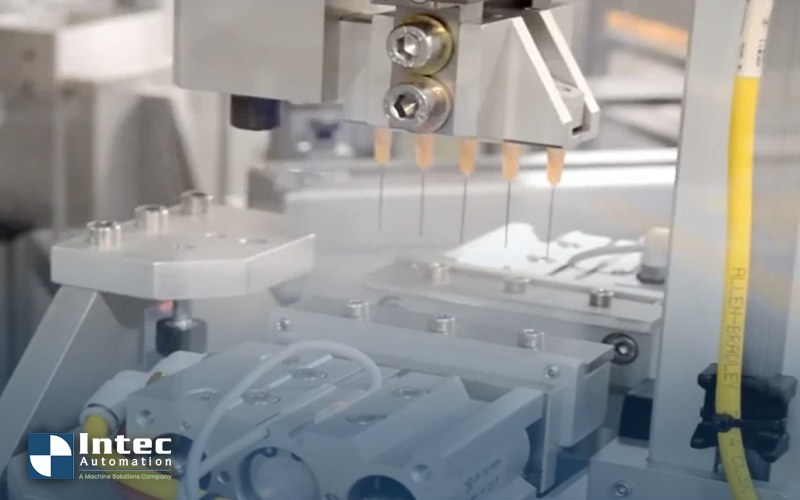

Blunt-tipped cannula needles typically include geometry features such as tip crimps, angle bends and radius form bends. When produced manually, the sequence may begin by removing the protective sheath from the product, and then the needles are placed under a microscope. The operator must then orientate the tip crimp angle to the bend angle, and the needle blank must be bent to the desired angle or radius. The finished product is inspected and then returned to a protective sheath.

Blunt-tipped cannula needles typically include geometry features such as tip crimps, angle bends and radius form bends. When produced manually, the sequence may begin by removing the protective sheath from the product, and then the needles are placed under a microscope. The operator must then orientate the tip crimp angle to the bend angle, and the needle blank must be bent to the desired angle or radius. The finished product is inspected and then returned to a protective sheath.

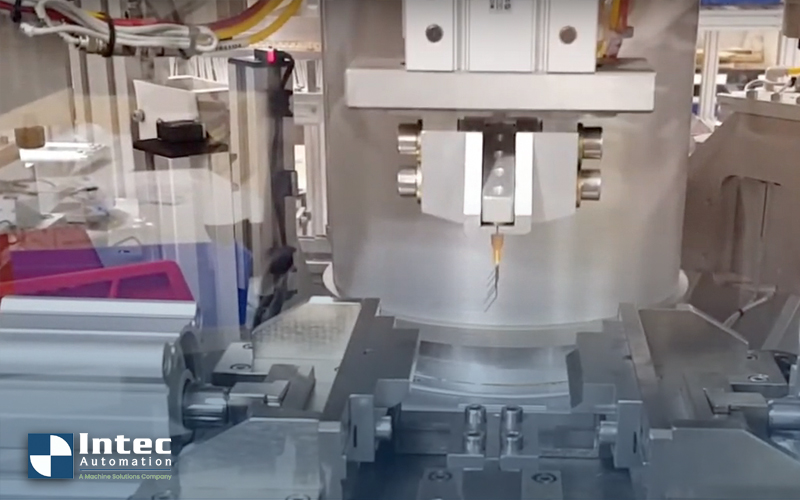

Because there are so many variations, an automated cannula machine can include hundreds of recipes. Some recipes only have a tip crimp, and some also get an angle bend. Some get a radius form and some don’t get any of those things. Any permutation of gauge, size, cannula length, hub type, angle bend, form bend geometry, and radius form can be included, so hundreds of combinations must be available on one machine. Manually doing tooling changeovers can cause lengthy downtime, especially with runs that require a high mix and low-volume production. However, quick tooling changeover can be done in under a minute with automation.

The manufacturing process is similar when blunt-tipped cannulas are processed on a machine with multiple stations. The first station removes the protective sheath. The second station might crimp the tip at either o degrees or 90 degrees. The third station could perform the angle or radius from bending. The fourth station could make a visual inspection, and then the final station could resheath the finished product and then drop it into a bin or downstream packaging.

Intec Automation are experts in asking and understanding the details of your manufacturing process to ensure your cannula-forming operation is optimized for your unique process requirements. Check out this case study video where we converted a manual cannula-forming process to an automated operation for a tier-one medical device manufacturer:

A production run of the sharp cystotome-style cannula needles, which are micro-tubes that come in a wide range of shapes and sizes, is similar to the sequence above in that cystotomes go through a series of stations during production. For example, the first station could remove the sheath; and then the second station could rotationally orient the needle to get it into the proper position. The third station could bend the tip, and the fourth could inspect the bend. The next station could perform an angle or radius form bending, followed by an angle or radius form inspection or a geometry inspection. The final station could resheath the finished product and then drop it into a bin or downstream packaging.

Manual operations of cystotome cannulas performed by a single human operator can only produce an estimated maximum yield of less than 300 units per hour, plus the operator is exposed to sharp needles, which is less than ideal. In a recent project, Intec’s automated machine increased throughput by a minimum of 10 times and produced 3,600 finished parts per hour with a blunt tip machine and 600 finished parts per hour with a cystotome machine while improving overall product quality.

Manual operations of cystotome cannulas performed by a single human operator can only produce an estimated maximum yield of less than 300 units per hour, plus the operator is exposed to sharp needles, which is less than ideal. In a recent project, Intec’s automated machine increased throughput by a minimum of 10 times and produced 3,600 finished parts per hour with a blunt tip machine and 600 finished parts per hour with a cystotome machine while improving overall product quality.

Automation of this tedious chore also means a consistent performance with a high degree of accuracy, precision, and repeatability. It enables a lower risk of contamination of the product because there is little to no human interaction during the manufacturing process. At Intec Automation, we understand your challenges with cannula assembly because we help customers with this all the time!

Intec Automation has decades of experience designing and building automated needle bending, forming, and crimping solutions, and can help you reach high-volume cannula production with a high level of customization. Our multiple inspection stations will ensure that you manufacture only the highest possible quality products.

Recent advances in a variety of prophylactic and curative treatments have increased the demand for application specific custom bent or formed needles...

Cannulas are small tubes that are primarily used to deliver or extract fluid. They are used in many different industries, with a high percentage...

Automation is adding new efficiencies across every manufacturing sector due to a constrained labor market. For medical manufacturers, the growing...