Making the Most Out of Your Routine and Scheduled Maintenance

When it comes to maintenance, we recommend all manufacturers develop a consistent schedule of routine and semiannual maintenance to prolong...

In the medical industry, many of the tools used by medical professionals for patient diagnosis and treatment procedures are single-use. Examples include nasal and oral swabs, PCR tubes, test tubes, laminar flow test strips, syringes, needles, pamphlets, and desiccant pouches. This equipment is often assembled and packaged into kits to facilitate safe and sterile transportation and storage until it is needed.

As the medical industry expands to service broader areas and higher volumes of patients, the demand for preassembled medical kits has increased.

As the medical industry expands to service broader areas and higher volumes of patients, the demand for preassembled medical kits has increased.

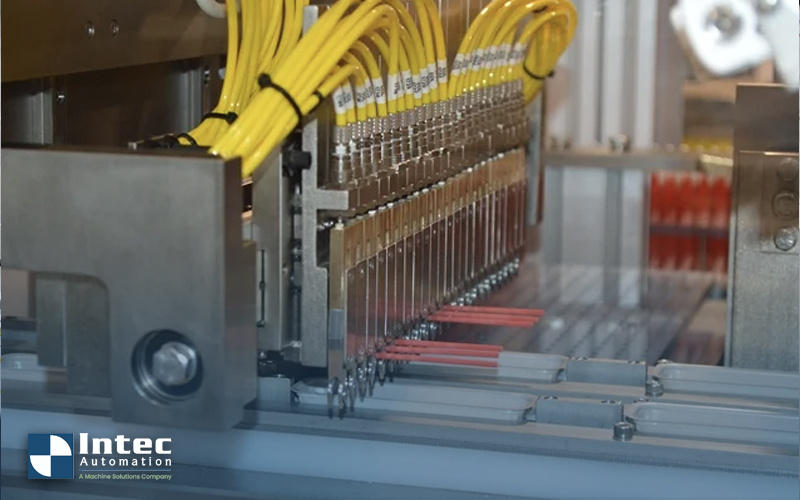

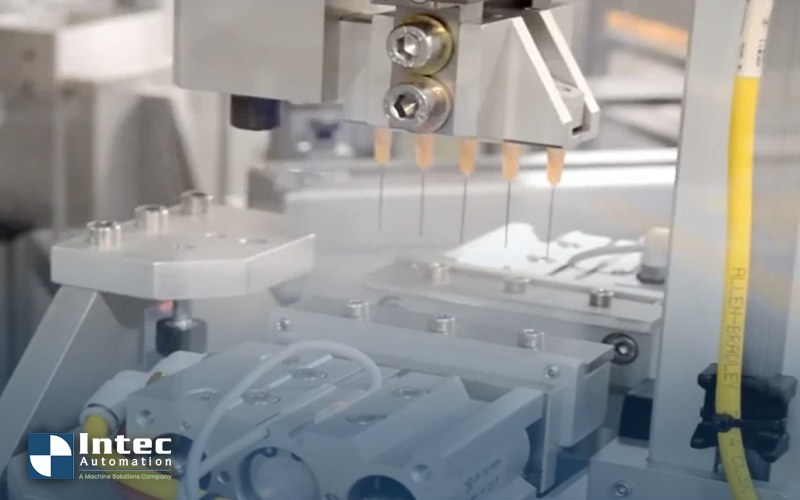

Many medical equipment and supply manufacturers rely on automation equipment to increase supply to meet demand. The automated equipment enables them to rapidly and reliably manufacture, assemble, inspect, and package products with little to no involvement from human operators. As a result, they can achieve higher production outputs with lower labor costs as well as increased quality control.

The assembly process often involves precise and repetitive motions. Medical kit assembly operations are no exception. By using automated equipment, facilities can decrease the amount of time needed to perform operations and increase the throughput at which kits can be completed. Other benefits include:

Automated systems are less likely to make operational errors than human workers, resulting in overall higher product quality and lower process variability.

Automated assembly equipment can be programmed to accommodate different parts and products, enabling manufacturers to add or remove operations as needed to produce different kits.

Automation allows the realtime application of 1D and 2D barcodes and unique lot numbers with inline printers and scanners, improving product quality control and traceability, as required by the controlling federal agencies.

While automated medical kit assembly systems are primarily used by companies within the medical industry, the same technologies can be used by companies in adjacent fields. For example:

While automated medical kit assembly systems are primarily used by companies within the medical industry, the same technologies can be used by companies in adjacent fields. For example:

At Intec Automation, we are committed to helping customers in the medical, life sciences, and pharmaceutical industries improve the quality, safety, and efficiency of their production operations. Equipped with 20+ years of expertise in the medical device assembly and kitting industry, we design, build, and integrate custom equipment and systems that ensure product quality and improve throughput.

To learn more about our automated system solutions and how they can benefit your manufacturing and production, contact us today. We can customize your automated system to your application with a variety of elements to improve operation and performance.

When it comes to maintenance, we recommend all manufacturers develop a consistent schedule of routine and semiannual maintenance to prolong...

Automation is an increasingly attractive solution in manufacturing. Finding skilled operators and retaining them is a problem that continues to...

Recent advances in a variety of prophylactic and curative treatments have increased the demand for application specific custom bent or formed needles...