Minimize Manual Product Handling in Diagnostic Device Assembly

Manual steps remain common in diagnostic device assembly, but they often create more challenges than benefits. High output requirements and strict...

1 min read

John A. Weismantel

:

Jan 7, 2026 12:11:02 PM

John A. Weismantel

:

Jan 7, 2026 12:11:02 PM

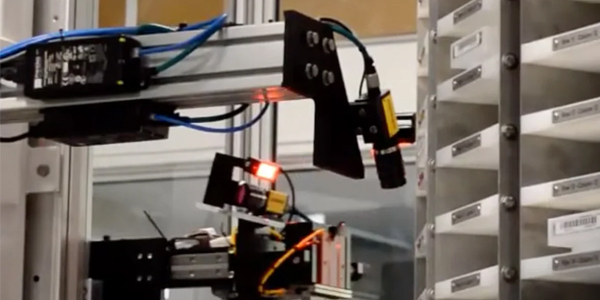

This discussion focuses on specialized expertise in the deployment and operation of ball bearing dispensing equipment, primarily within the life science space. These systems are designed to operate in various capacities, including standalone setups, integrated production lines, or as semi-automated replacements for benchtop machinery.

The critical challenge in handling ball bearings stems from their nature as spheres made of extremely hard materials like tough steel or hardened stainless steels. Because any point of contact with a sphere acts as a point load, the surface area is infinitely small, resulting in a theoretical infinitely high stress that can easily create dents and damage whatever the ball bearing touches.

Overcoming these unique handling difficulties has led to developed expertise in crucial areas, such as selecting the proper materials, coatings, and distribution approaches—including the use of specific tubing or plastic singulation plates—to ensure successful operation.

Our experience and expertise in ball bearing dispensing and equipment has been primarily in the life science space, and it's to deploy systems, whether they're standalone or integrated into a production line or they're semi-automated, replacing just a benchtop type machine.

We've deployed systems in all of those types of applications. And the expertise around ball bearing dispensing comes from a lot of lessons that we've learned through doing those systems.

Ball bearings are a unique material to handle because they're they're spheres and they're typically made out of very hard and tough steel or hardened stainless steels. And so they can destroy everything, right?

So, with a sphere, you have contact points that are point loads to everything that they touch. And so, with a point load, you have an infinitely small surface area and in theory, an infinitely high stress. So, whatever force gets transmitted through that ball gets distributed to a point and therefore likes to create dents and damage anything that it comes into contact with.

So, some of the expertise that we've developed is um selecting the proper materials, proper coatings, proper distribution approaches, whether it's using tubing or special plastic singulation plates.

Manual steps remain common in diagnostic device assembly, but they often create more challenges than benefits. High output requirements and strict...

Custom automation success goes beyond specs and software; it comes down to choosing the right people. The right integrator helps you avoid delays,...

Product failures borne from low-quality design or inadequate manufacturing processes are simply unacceptable for medical device OEMs. The liabilities...