The Design and Build Process for a Complex Automation Assembly Cell

The clean sheet design and build of custom automated solutions for complex manufacturing applications requires a system integrator with a proven...

3 min read

Corey Marcotte

:

Oct 21, 2024 8:30:00 AM

Corey Marcotte

:

Oct 21, 2024 8:30:00 AM

Finding the right custom automation partner is about more than just machinery. It's also about the ongoing support that keeps your operation running smoothly.

When surgeons are using life-altering medical devices that they manufacture, quality issues are of the utmost importance. Medical and life sciences manufacturing sectors demand precision, reliability, and strict adherence to ever-changing regulations, making a custom automation partner with professional service and support capabilities crucial.

One issue that all manufacturers have experienced is when your custom automated machinery begins to malfunction, causing poor quality products, downtime, and plenty of your operator’s time to try to fix. Really, what we hear their manufacturers want is help to solve the problem immediately. With Intec Automation, we are there for immediate support but also work to reduce the chance of downtime before it happens. We work with our customers to design the best solution to factor in issues on the front end when designing systems.

From getting you the right parts replaced to sending a technician to your site, your automation partner should have you covered with fast response times that won’t leave your production line down.

From getting you the right parts replaced to sending a technician to your site, your automation partner should have you covered with fast response times that won’t leave your production line down.

Starting when a new automated system is installed, you want to know that your automation partner will do more than drop off the equipment and leave you with nothing but a handbook. You need a team of experts who will be there from day one, offering customized training that makes sense to your operators. And when it comes to Factory Acceptance Tests (FAT) and Site Acceptance Tests (SAT), you want a partner as invested in passing them as you are.

The long-term value of automation investments rests partly on proactive maintenance and support. Your organization will inevitably rely on automation partners to offer preventative maintenance schedules that align with your equipment usage patterns. Even better, remote monitoring and predictive capabilities can significantly reduce downtime.

Overall Equipment Effectiveness (OEE) is the goal. To enhance your output quality, you need a partner who provides continuous performance monitoring and data-driven process improvement recommendations. Achieving at least 85% OEE in availability, performance, and quality is essential if custom automation is to run at peak efficiency.

Additionally, partners should take a proactive approach to engineering solutions. This includes identifying necessary design improvements, implementing redundancy measures, and fostering relationships with component suppliers to encourage long-term support. They should be thinking three steps ahead, identifying potential issues before they become real-world setbacks.

How does this partnership look in action? Take the case of a Tier 1 medical supplier new to automation. The organization faced challenges implementing a complex machine with limited in-house expertise. Through close collaboration during startup and ongoing remote support, their partner, Intec Automation, ensured successful implementation. This success catalyzed the expansion of automation initiatives across the company and its parent organization, demonstrating the transformative potential of expert support in heavily regulated industries.

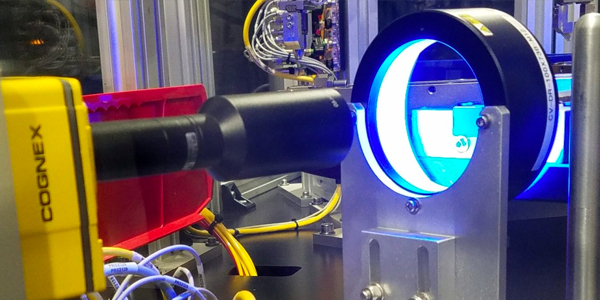

Top-tier custom automation partners don't just react to problems—they anticipate them. Take, for example, the approach to designing a machine that applies PSA film to a multi-well plate. In this scenario, even the tiniest debris can compromise the integrity of the test unit. A forward-thinking partner addresses this challenge starting at the design phase, implementing solutions like vacuum systems to minimize particulate contamination.

When evaluating custom automation partners, prioritize those with a proven track record in health and life sciences projects who are particularly familiar with the regulatory landscape. Look for proof of their commitment to long-term client success references from established clients and review their roadmap for future support and technological advancements.

Selecting the right service and support partner in custom automation can make or break your manufacturing operation. You need them to handle initial implementation and provide ongoing support to keep production running smoothly for years to come.

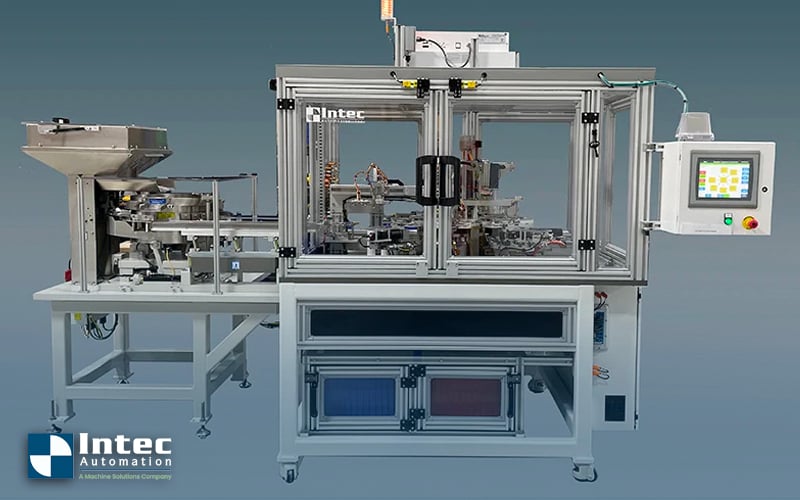

Intec Automation specializes in tailored automation solutions with comprehensive service and support for high-stakes industries like health and life science. Our team's technological expertise spans from initial concept development to ongoing system optimization, with a deep understanding of the industry's unique challenges.

To learn more about choosing a custom automation partner, download our eBook: "Checklist & Guide: How To Select a Partner for Custom Automation." This resource offers practical tools and in-depth information to guide your decision-making process in automation partnerships.

The clean sheet design and build of custom automated solutions for complex manufacturing applications requires a system integrator with a proven...

Widely used in the medical field for surgery or in optometry, cannula manufacturing assembly can vary greatly with the needle length, geometry,...

Machine vision and computer vision systems both perform image processing to analyze data about a product or process. Both typically consist of a...