Corey Marcotte Featured on Made in New England Podcast Series: Medical Device Manufacturing

Steve DeVries of the Made In New England - Podcast Interview Series sat down with Corey Marcotte, President of Intec Automation, as he shared his...

2 min read

John A. Weismantel

:

Feb 14, 2022 2:53:37 PM

John A. Weismantel

:

Feb 14, 2022 2:53:37 PM

Automation has increasingly become a necessity for manufacturers of medical kits and medical device equipment to stay competitive and to keep up with demand. New technologies in automated equipment quickly and reliably assemble, inspect, and package kit components with little to no human intervention. This enables manufacturers to increase production, reduce costs, and boost quality control.

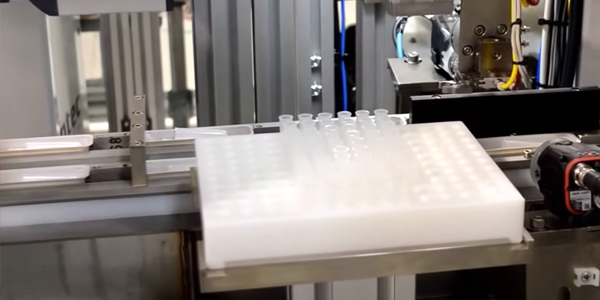

A large variety of medical kits and devices can be produced and assembled via automation. For example, single-use tools such as PCR tubes, nasal swabs, oral swabs, test tubes, laminar flow test strips, needles, syringes, desiccant pouches, and pamphlets can quickly and easily be assembled and packaged into sterile, transportable kits at higher volumes. This was especially important during the COVID-19 pandemic with the need to expedite medical supplies to the marketplace.

Automation also makes the whole process of manufacturing, quality checking, and transporting medical kit assemblies more responsive to demand. For example, assembling medical kits requires precise, repetitive motions.

Automation also makes the whole process of manufacturing, quality checking, and transporting medical kit assemblies more responsive to demand. For example, assembling medical kits requires precise, repetitive motions.

When using automation, production facilities cut the amount of time necessary to create and assemble these kits correctly, thereby getting these tools into the hands of medical professionals who need them quickly.

Some examples include:

Saving time and reducing infection transmission are two critical components driving demand for automation amongst medical device and test kit manufacturers. Statistics show that 44% of production facilities will increase their automated assembly budget this year. Medical, dental, and veterinary offices rely heavily on pre-assembled, disposable medical kits and tools because they increase efficiency, reduce costs, and prevent the spread of infection.

Furthermore, life sciences and medical device manufacturers can be hit with unforeseen circumstances impacting daily production activities and typical decision-making processes. With the global impact of COVID-19, it has become increasingly difficult for manufacturers to meet market demands for medical devices and tools. Automation offers a way to quickly meet product demands, even during challenging times. Now that companies have experienced the improvements automation has afforded in terms of improved production, quality, and agility to meet rapid demand changes, they can ramp up production to meet varying demands without the burden of fluctuating their workforce.

As the COVID-19 pandemic morphs into new phases, it is clear that medical manufacturing companies need to implement automation strategies to prepare for whatever comes next.

Key benefits of automation for medical manufacturers include:

Improved Safety And Reduced Human Error

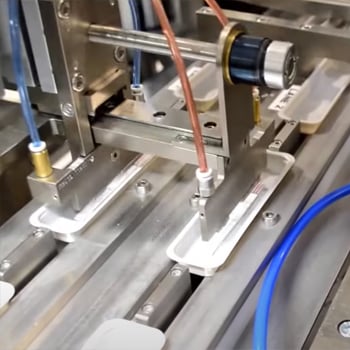

Improved Safety And Reduced Human ErrorThe highly advanced automation systems available today nearly eliminate operator errors that are endemic to a mostly-human workforce. This boosts safety for end-users, improves product quality by enhancing standardization across production lines, and improves safety for employees.

With the ability to program automated assembly production line equipment to create a variety of products precisely and quickly, manufacturers can easily customize the kits with a touch of a button.

Automated tools can produce both 1 and 2D barcodes, unique lot numbers, QR codes, and other traceable metrics to verify products for both quality control and to meet ever-changing federal agency standards.

Automation makes tens of millions of medical kit assemblies possible in a short amount of time. This results in a high level of quality and efficiency that can’t be achieved with a human-only workforce.

The COVID-19 pandemic continues to ebb and flow, and there is no telling what types of disasters or challenges could come next. Keeping employees safe is the number one priority for employers, but for medical manufacturers, things reach a critical point when the very tools that could save lives are in shortage. This is why automation is such a critical part of a disaster preparedness plan for medical manufacturers. It protects workers while ensuring that medical teams still have the supply of medical kits they need when they need them.

In an unpredictable world, automation can help manufacturers prepare for future challenges. Contact us today to discuss your needs with our automation experts.

Steve DeVries of the Made In New England - Podcast Interview Series sat down with Corey Marcotte, President of Intec Automation, as he shared his...

So, what is the difference between blunt needles and cystotome cannula needles? Blunt Cannula needles are thin, hollow tubes with blunt ends which...

In this video blog, John Weismantel, the Vice President of Engineering at Intec Automation, dives deep into the electronic circuit tester solution....