AUTOMATION STREAMLINES THE ASSEMBLY & MANUFACTURING OF MEDICAL DEVICES AND TEST KITS

Automation has increasingly become a necessity for manufacturers of medical kits and medical device equipment to stay competitive and to keep up with...

10 min read

Kate Crossan

:

Feb 15, 2024 10:51:00 AM

Kate Crossan

:

Feb 15, 2024 10:51:00 AM

Steve DeVries of the Made In New England - Podcast Interview Series sat down with Corey Marcotte, President of Intec Automation, as he shared his story and his thoughts on what got him to this point, including befriending the grumpy guy in the corner!

You can check out the interview video below or continue reading for the transcription.

Steve: Hello and welcome to the Made in New England interview series where we talk with New England-based companies and people who lead them. I'm your host Steve DeVries and today I’m joined by Corey Marcotte who is president of Intec Automation based in Rochester, New Hampshire. Welcome to the show.

Corey: Thanks Steve, thanks for having me.

Steve: You are very welcome, glad to have you. Would you like to kick us off with a little bit of background about yourself and your business?

Corey: Sure, so this show is based in New England and I’m a New England kid, born and raised in Laconia, New Hampshire. Went into the military in the early 90s, came back, and used the University of New Hampshire to get an engineering degree and have pretty much worked my whole career in New England and have supported other sites across the United States and internationally but typically I’ve stayed in New Hampshire.

Steve: Excellent, so tell us a little bit about what Intec Automation does?

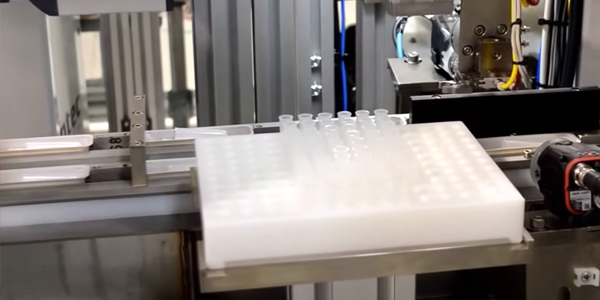

Corey: So Intec is a custom automation warehouse, so we have been doing this for 23 years now. We supply medical and life science customers with custom automation equipment for assembly. Some of the tier-one medical customers; sutures, needles, medical devices, and assembly. We have mechanical engineers/electrical engineers on staff who design specialty equipment that couldn't get off the shelf. We come in with a problem and we come up with a solution with mechanical-electrical engineers and we procure or manufacture the components, build the machines, and deploy the systems into other manufacturing facilities across the world.

Steve: Sounds like a lot of fun, you must see a lot of unique applications out there given the clients you are working with.

Corey: Yeah, it's great. We are kind of a boutique automation shop so we get to design some neat things and we get exposed to a lot of cool emerging technologies that our customers need help with. So typically when automation happens they do prototype stages with operators and then it goes into higher production. It gets validated by the FDA, gets approved, and then they have to produce it for the masses and that's where the automation piece comes in. We work with our customers from the conceptual phase to the production phase.

Steve: Exciting, so everything you do is more or less one-off. I have to ask, we both are in manufacturing and we both have operation backgrounds; how do you manage a business with so many new things coming through all the time? In terms of metrics, what metrics or KPIs do you use so you know the business is running the way you want it to?

Corey: That's a good question. This business is typically small mom-and-pop companies or very large companies like ATS or something like that's publicly traded. And it’s very difficult, so it’s clever engineers coming up with new solutions. So when you are doing it the first time, it's very difficult; it's like stepping up to the plate and trying to hit a home run with every pitch. It can be very costly. I've been with the company for 9 years now.

I started some metrics where we were looking at, conceptualizing what the solution should be from a mechanical perspective, and what that means is it needs a rotary table, it needs a platform, it needs a frame, it needs a robot, it needs an automation system. Once we have conceptualized it, we can build the machine to do the solution for the customer. We will build the materials and get a cost for the build materials and over time I have been collecting data throughout all the projects on direct labor so assembling the machines, mechanical engineers' hours, electrical engineering hours, and cost to console that bottom cost.

We have created a unique formula for ourselves that we can extrapolate from. So depending on complexity and what the bottom cost is we can forecast what the price needs to be. The biggest sale for us is, sometimes it comes in more expensive than the customer needs. So another thing that we do on our side is; so Steve has an application and he has X amount of dollars, say it $100,000 and he has this list of hey I want the machine to do this, this and this. You need $500,000 for your solution if you want to do all those things. What are the critical components? So I try to work with the customer upfront and say what’s your ROI? What do you have that’s critical for the operation and we go back and forth to build a budget together. If they can't afford certain things, maybe they can put those operators in positions outside of that. So if they're not critical to quality, we can maybe have an operator load parts in or unload parts in.

We don't have to make this fully automated and I try to do a lot of that stuff upfront. It’s not a guessing game. With the data we have created, we built up our sales team to four individuals now. I've taught them that lesson now and we continue to be very successful over the years.

Steve: I love that, it's not just hey we need this piece of equipment, how much will it cost and can you build it for? You really are an extension of their engineering team when you partner with them to do that type of thing.

Corey: Yeah, we supply a machine at the end of the day, capital equipment, whatever you want to call it. But really we are a service-based company. People come to us with a problem, we can design a solution for them and deploy a system that is going to help them. But, they need to understand that it's not just off the shelf, it's a partnership. So every one of our customers is a partner. Once they have a project with us we maintain the relationship. Yes, we do one offs but our goal is to build long-term relationships with our customers.

Steve: I love that, so switching gears a little bit now that we understand business and the type of value you provide. Let’s talk about what you see in the future. What excites you most about the future of your business?

Corey: We do have a bubble in diagnostics. We are in the life science and medical phase so most of our business comes from those avenues. What had happened was shortages of parts during COVID, which was very tough for us and many manufacturers. Long lead times, so I think the onboarding of manufacturing back to the US is going to be very helpful, so that's a positive thing that I see. Some of the negatives were the cost of the components being so high, lead times were really problematic.

When you work with Intec when we receive a purchase order with a fixed timeline and a fixed budget, a certain amount of money we will deliver a certain product at the end of the day with a certain timeline because you need the product to start making money for yourself. During COVID and going into the future lack of parts like a robot or a camera that had a long lead time, projects started to grow in length so we had to figure that out. What happened in ‘22 was we got acquired by BW. They are a manufacturing company that has a bigger relationship with key vendors and part of our success which was a gap for us was now we have global relationships.

As a smaller company in New Hampshire, it was tough for us to leverage some of that power. We are now part of a bigger company and that's mitigated some of that risk. I think the future is very bright for us. And BW’s is people-centric and we are people-centric so it’s been a great transition for us as a New England-based company. It’s been perfect, the team really likes the experience and it's like having a big brother, it gives us a safety net. But we can still work autonomy for ourselves to grow the business. It's been great. I’m excited about the future, honestly.

Steve: Very exciting! So, now flipping that around, we always have some concerns, some things that we have in the back of our minds or keep us up at night. Industry-wise or global economic conditions, geopolitical situations; does anything like that concern you in the near term or long term for the business?

Corey: So, strategically my background is mechanical engineering. I have an MBA and a minor in finance so when I took over Intec my first thought was diversification makes a lot of sense. That's going to flow through economic times and all these things. Put energy into automotive, aerospace, medical, life science, and what I quickly realized is aerospace and some of those automotive buckets; there's a lot of automation but they are very cyclical and risky. So we made a conscious decision probably six years ago to only focus on life science and the medical, and I think that was a smart move for us.

I think those markets are going to continue to grow as we continue to grow. There is an aging workforce with a lot of medical advancements so I think it was smart for us to kind of push in that direction and we are marketing and selling in those directions.

We also still like the high-tech and emerging markets and industries because it's new and it could be the lightning in the bottle so we need to pay attention to some of those applications where we are going to potentially see some new growth, or we want to stay in touch with those emerging. So emerging markets medical and life science are kind of our key industries that we are marketing and I feel pretty confident that those are going to ramp up in the right direction.

Steve: Nice, you mentioned something that I wanted to ask you about; an aging workforce. So it sounds like you are employing primarily engineers, mechanical and electrical engineers. I know a lot of business leaders have concerns about the workforce. Do you see any change with that in the future or are you feeling pretty confident in what you are seeing for potential employees?

Corey: I was just talking to our engineering manager this morning and said we need to start working on a mentor-mentee program. So we have some of our senior engineers who are getting into their 60s and close to retirement and we need to do a transfer of knowledge. The stuff that we do is not something they teach in mechanical engineering school, it's really hands-on experience. You can come out of engineering school and you don't know how to design custom automation equipment.

You have to do it to experience it and a couple of the books I've been reading were talking about master programs and apprentice programs and how that's kind of gone away. Historically it's kind of been the way machinists, electricians, plumbers, and these trades but were not doing a good job in manufacturing and engineering industries.

We have worked with a couple of universities, we had three interns last summer from UNH, we picked up a couple of kids from the electrical program at Granite State College, and we have actually hired one. She is full-time with us now. We are conscious of it and we are working with universities and are trying to leverage our internships to full-time employees.

Steve: That’s exciting, so going back to the New England theme; you mentioned you are born and raised New England kid. You used the New Hampshire state school system for your degrees. In terms of having your business located here in New England, do you see pros or cons in that regard?

Corey: I would say pros- my previous job was North American operations manager and we had facilities in Mexico, Canada, and all across the United States. I had exposure to a lot of manufacturing environments and their people. When it comes to New England folks, Maine, New Hampshire, Massachusetts; they are hard-working, they are dedicated, they are a little matter of fact, a little rough but they get the job done.

I think being founding fathers, they are pretty mechanically inclined, they are hard workers. They work on farms, they fix their own stuff, and they build their own houses. It's pretty unique to this area. Not saying there aren't clever people everywhere else because there are, but I think it's a positive for sure.

Steve: Last question Corey, you got your engineering degree and worked your way up and you have held senior-level positions now president of a major automation company here in New England; any advice you have for budding business leaders or maybe students getting ready to graduate who might want the same type of career track that you’ve had.

Corey: I had many jobs throughout my career from the military to my first internship as an engineer. I always try to find someone that wants to share their knowledge. When that knowledge was exhausted I would find someone else. I was always just hungry to find someone that wanted to help. Sometimes as a young kid who wasn't a senior engineer, that was a guy on the floor who actually knew how to torque bolts better than I did.

There was an old grumpy guy, but if you went over and asked him a question, he was like who is this kid right? And you are willing to befriend them, and everyone is willing to offer what they know so instead of being a kid coming out of engineering school thinking that you know everything, open your eyes and see who the grumpy guy over in the corner that's doing a good job that you want to learn about welding or machining.

Once I got a lot of that stuff locked down I was looking at my career path and where I wanted to go, so I shifted from a smaller company where I learned a lot of stuff but I was a little exhausted after five years and what I could get from the company.

I was making a good salary, and I liked the company but I needed another challenge so I shifted over to a different company where I knew they were doing everything from a large machine shop. Building to field service, and I wanted to get exposure to that stuff. So put yourself into situations that feel a little uncomfortable and when you get into those situations ask questions. The next move I looked around and everyone that was managing engineering groups had MBAs so how do you get an MBA? Where do you go to do it? So start looking into opportunities like that with tuition reimbursement. I worked for a company that paid for my MBA. Companies want these young people who are eager to learn and grow.

I think if you have that growth mindset throughout your career that will be your success. Don’t expect it all in the beginning. I think you have to put in the work to get to where you are going. So coming out of school you just want to be the president of a company is not all it's cracked up to be. It's a lot of responsibility. All the stuff I did to get to this point I leverage every day. You need to have that in your toolbox, if you don't have it you're not going to be successful in that next step. Building those tiers for future success makes a lot of sense. It's what has worked for me.

Steve: Lots of great advice, and Corey and I've really enjoyed your story about the grumpy old man in the corner who knows how to torque bolts better than you; I know that guy and there's a ton of value in building relationships with the folks that have been doing it a long time.

Corey Marcotte, thanks so much for your time today and for joining me. It was great meeting you and learning all about you and something about Intec as well. We really appreciate you being on the show. Thanks for watching and listening. We will be back another time soon with another episode. Have a great day.

Automation has increasingly become a necessity for manufacturers of medical kits and medical device equipment to stay competitive and to keep up with...

Over the last few decades, contract manufacturing has become an effective business strategy for expanding organizations. However, recent disruptions...

So, what is the difference between blunt needles and cystotome cannula needles? Blunt Cannula needles are thin, hollow tubes with blunt ends which...