Common Problems & Solutions For Ophthalmic Cannula Forming Operations (Part 2)

In part one of this blog series, here we covered common obstacles with humans vs. automated medical device assemblies. We also covered issues with...

2 min read

John A. Weismantel

:

Jul 31, 2024 11:15:00 AM

John A. Weismantel

:

Jul 31, 2024 11:15:00 AM

In the ophthalmic cannula forming industry, pain points persist in the areas of ergonomic and operator safety, consistency, quality, profitability, and efficiency. But if you are working with the right automation partner, many of these common issues can be eliminated.

Operator safety and ergonomics are two major concerns when manufacturing sharp devices because operators are continually at risk of getting poked, cut, or even seriously injured. And if you have an operator frequently loading materials and then pushing a trigger button or operating a two-handed switch, those repetitive motions can be tied to carpal tunnel and other ergonomic challenges that lead to workers' compensation claims.

Humans can also unintentionally inject organic matter contamination into the manufacturing process. Or perhaps an employee is shaky from having too much coffee on Monday morning, and they may not load raw materials into the system the same way every time. Humans need to be trained, and they need breaks and get sick, they show up late for work, and they occasionally quit.

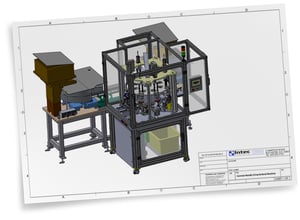

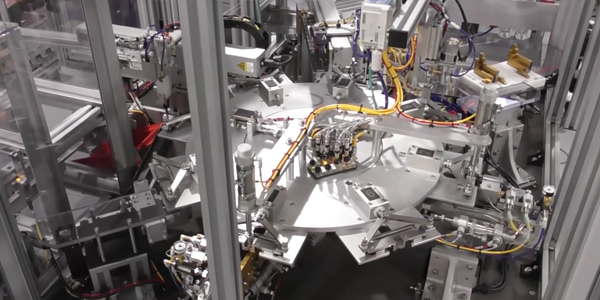

An automated cannula-forming machine can produce 3,600 parts per hour or more if required, one part per second, by performing multiple or concurrent functions. A human trying to load and unload a machine at that rate would find the task extremely taxing if not impossible.

An automated cannula-forming machine can produce 3,600 parts per hour or more if required, one part per second, by performing multiple or concurrent functions. A human trying to load and unload a machine at that rate would find the task extremely taxing if not impossible.

This can be a win-win for the employees and the company because automation can mean moving employees to higher-value tasks for manufacturing employees, allowing them to focus on things that aren't going to expose them to risks. By shifting these individuals to higher-skilled tasks, you can actually increase skilled labor jobs because of improved output and the ability to plan future production in the facility due to improved reliability. Here is a customer who found that to be true for their facility!

When a cannula gets inserted into a hub to be glued, there can be variations in the cannula tube length and the distance that it is inserted. Humans can compensate for these variations, but in order to get an exact geometry, a human must manually position everything in the forming die.

However, an automated machine with a vision system can automatically correct for length and distance and create a consistent end geometry. For example, if a customer wants an angle bend of 5mm from the hub followed by a bend of 45 degrees, and the final geometry is important, then it matters whether the start of the hub or the end of the needle tip is consistently the reference point. An automated system can compensate and create a consistent output geometry.

However, an automated machine with a vision system can automatically correct for length and distance and create a consistent end geometry. For example, if a customer wants an angle bend of 5mm from the hub followed by a bend of 45 degrees, and the final geometry is important, then it matters whether the start of the hub or the end of the needle tip is consistently the reference point. An automated system can compensate and create a consistent output geometry.

Variations in the raw materials also lead to variations in the finished product, and if your product deals with life-altering surgeries, then those variations are not acceptable.

A manufacturer is tasked with producing a product that falls within a customer's parameters, so if a human manufacturing employee can influence a geometry such that it falls outside of the required specs, and it isn’t caught in a downstream post-inspection, then the customer is more likely to have quality defects.

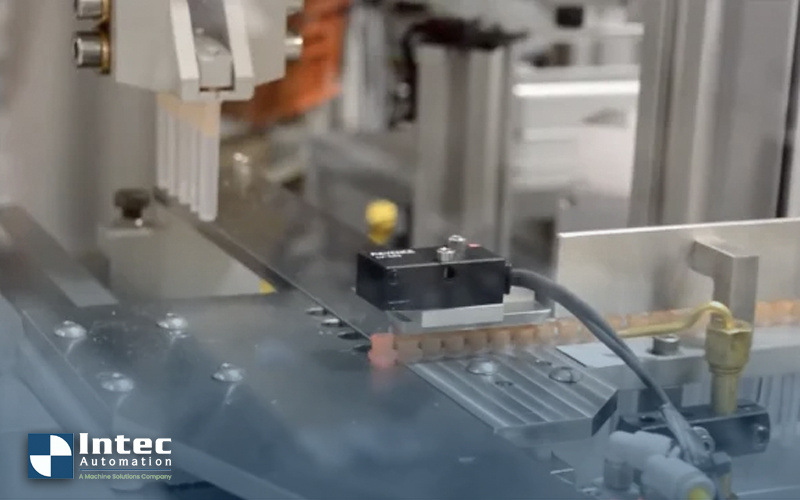

Process control systems can perform quality testing throughout a production line, and must be a high priority if using them means they remove defects of quality from a line.

The level of quality control that an automated system can reach could never be reached using humans alone. An automated system can perform quality testing throughout a production line, and will regulate production metrics, create and send you data, remove defects from a production line, and ensure that each product meets the quality inspection parameters.

In part two, we will continue to address common problems with manual vs. automated medical device assembly operations including changeover procedure headaches, up and downstream processing for cannula-forming operations, and how to make your life easier with automation!

In part one of this blog series, here we covered common obstacles with humans vs. automated medical device assemblies. We also covered issues with...

Widely used in the medical field for surgery or in optometry, cannula manufacturing assembly can vary greatly with the needle length, geometry,...

The COVID-19 pandemic has caused major interruptions to business operations within countless industries. As a result, many companies are looking for...