Applications of Automation in Medical Kit Assembly

In the medical industry, many of the tools used by medical professionals for patient diagnosis and treatment procedures are single-use. Examples...

1 min read

John A. Weismantel

:

Mar 18, 2025 10:00:00 AM

John A. Weismantel

:

Mar 18, 2025 10:00:00 AM

Juan Cardenas, our Vice President Sales & Applications Engineering, describes our process of mitigating risk involved with the design and build of your automation system through the process of prototyping. Before moving into building the full automated system, we are able to test the functions involved in your solution to make sure that they will meet all of your needs.

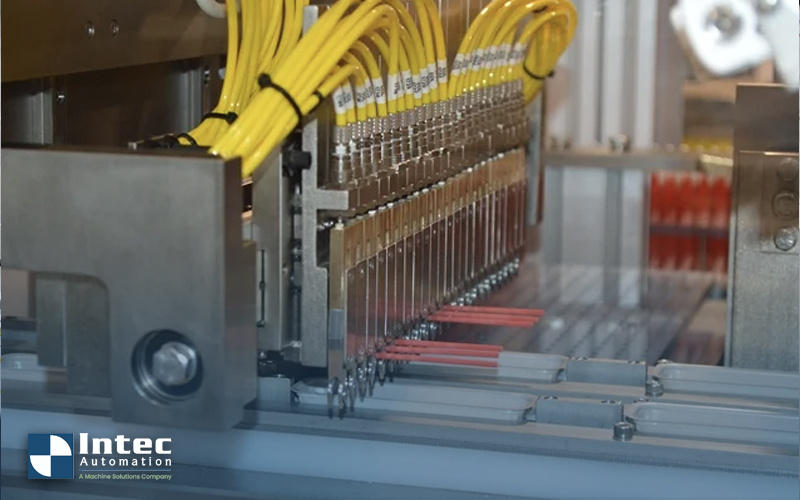

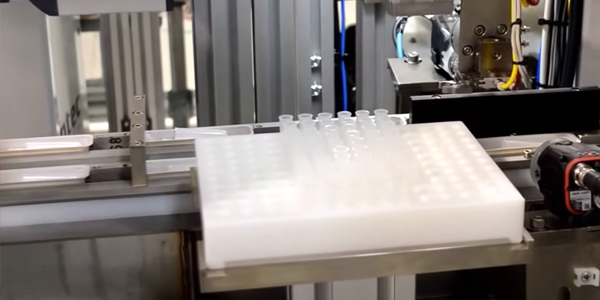

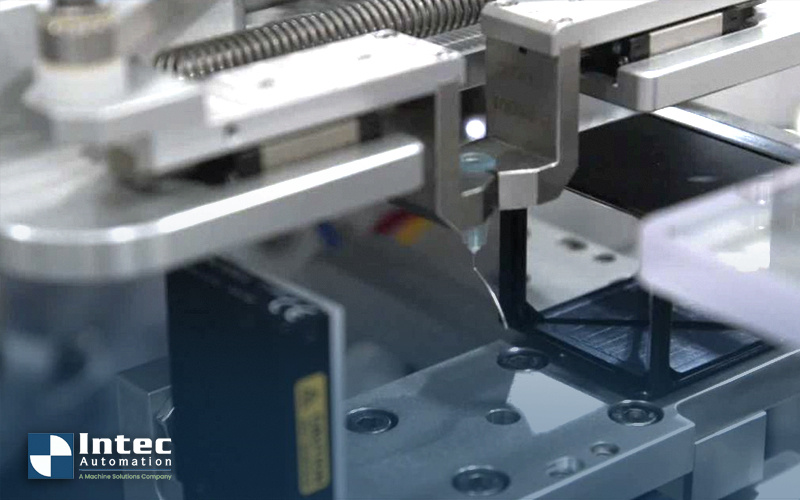

Intec Automation designs and builds custom equipment. It's not standard equipment, it's not something we have ever built before. There are risks in doing that. Sometimes we encounter that some of those risks could be in cycle time. Are we able to meet the cycle time on the particular operation that the customer wants? Or, are we able to meet the quality? For instance, can we dispense a very expensive reagent with a tolerance that the customer is looking for?

There is always a risk, but what you don't want is to build the full machine and then hope that the particular process meets the requirements. What we do to mitigate the risk is propose to the customer, what we call, Proof of Principle (POP) or Proof of Concept (POC). This is where we say, we are not going to build the whole machine, we are just going to mimic that particular operation. Sometimes it's with hardware that we have in-house. Sometimes we have to buy some of that hardware or machine some of that hardware. But, you do an experiment to prove to them and to us that we can achieve that cycle time. We can achieve that quality. We can feed those parts reliably. There are many ways of doing that and many applications.

Once we solve that problem and we feel comfortable, we move to the next phase which is now building the whole machine. Our responsibility to the customer is to eliminate (as much as possible) the risk.

We offer world-class machine design, controls engineering, program management, industrial technology and manufacturing engineering. Our team of highly experienced professionals are ready and waiting to assist you with your custom automation needs today.

In the medical industry, many of the tools used by medical professionals for patient diagnosis and treatment procedures are single-use. Examples...

Automation has increasingly become a necessity for manufacturers of medical kits and medical device equipment to stay competitive and to keep up with...

John, our VP of Engineering at Intec Automation, is diving deep into the different considerations for needle bending equipment, tooling, and...